Engineering the Shift

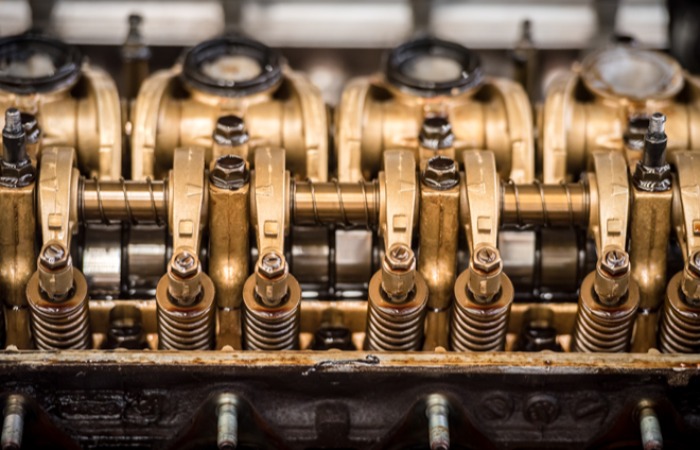

In the world of construction, where heavy machinery drives progress, there is one unsung hero: the power transmission system. These complex systems are the beating heart of construction equipment, converting engine power into usable mechanical force. Without efficient transmission systems, bulldozers, cranes, and excavators would struggle to perform at their best. As the construction industry evolves, the demand for smarter, more efficient, and sustainable transmission systems has never been greater. Today, market leaders are stepping up to meet these demands with cutting-edge technologies, automation, and innovations that promise to revolutionise how construction equipment operates.

In the fast-paced world of construction, where deadlines are tight and precision is paramount, the need for reliable and powerful transmission systems has never been more crucial. With infrastructure development projects booming globally, especially in emerging markets like India, the demand for construction equipment is surging. As construction activities become more specialised, the requirements for the transmission systems that power these machines are also evolving.

Construction equipment today must deliver more than just power; it must do so efficiently, sustainably, and without compromise. Whether it's for heavy-duty bulldozers or material handling equipment, the expectation is clear: transmission systems must enhance efficiency, performance, durability, and operator comfort, all while reducing environmental impact.

Shift towards efficiency and sustainability

The shift towards more sustainable and energy-efficient construction machinery is a global trend driven by tightening emission norms and the push for greener technologies. Hybrid and electric construction equipment are increasingly becoming part of this transformation, with their specialised transmission systems that can handle unique power needs. Power transmission solutions are evolving to accommodate these electric drives, with energy-saving technologies like regenerative braking systems being integrated to recover energy during deceleration. These systems are crucial in ensuring that construction machines run efficiently while reducing their carbon footprint.

“The growing focus on sustainability is one of the key drivers for innovations in transmission systems,” says Seshan Iyer, President, Bearings & Industrial Solutions, Schaeffler India. “As more construction equipment moves toward hybrid and electric powertrains, we’re developing transmission systems that can efficiently handle these new power demands while also contributing to the green transition.”

Technological advancements

Automation is another transformative force reshaping the landscape of construction equipment. The advent of autonomous machinery, such as self-driving bulldozers and cranes, has made power transmission systems more sophisticated. Today’s systems are not just about moving power from one place to another—they are increasingly being integrated with advanced sensors, predictive maintenance technologies, and condition monitoring systems. These smart systems enable real-time monitoring of performance, allowing for predictive maintenance that can reduce downtime and extend the lifespan of equipment.

For example, Schaeffler India’s OPTIME Ecosystem combines condition monitoring with lubricant management, providing real-time insights into machinery health. This system helps operators identify potential issues before they cause a breakdown, leading to increased equipment availability and improved operational efficiency.

“Our goal is to ensure that construction equipment operates with minimal downtime,” says Iyer. “By integrating smart sensors and real-time monitoring technologies into transmission systems, we can predict failures before they occur, ensuring that the equipment is always ready for the task at hand.”

Market leaders innovate

Several companies are at the forefront of innovation in transmission systems for construction equipment, each bringing unique solutions to the table.

PowerBuild has long been a name associated with durable, high-performance geared motors. With products like the Series M, Series C, Series F, and Series K, PowerBuild is catering to the diverse needs of the construction industry. These geared motors are engineered to deliver optimal torque, high efficiency, and reliability in the most demanding environments.

The Series M (helical inline geared motors) is known for its compact design and exceptional drive solutions. With torque capacities of up to 20,000 Nm and power handling up to 160kW, this series is ideal for applications that require quiet operation and high efficiency. Similarly, the Series C (right-angled heli-worm geared motors) is designed for compact spaces, offering torque capacities up to 10,000 Nm, making it the go-to solution for precise applications.

According to a company spokesperson, “We engineer our products to deliver reliability in the harshest environments. Whether it’s for hoists, cranes, or conveyors, our geared motors ensure optimal performance, minimal noise, and maximum durability.”

Schaeffler India, a global leader in bearings and industrial solutions, has been making significant strides to meet the growing demand for construction equipment in India. The company’s investments in local manufacturing and R&D facilities have positioned it as a key player in the Indian market.

In 2023, Schaeffler expanded its Savli Plant in Gujarat, adding over 10,000 sq m of production space. This expansion allows Schaeffler to localise production of key transmission components, ensuring quicker turnaround times and greater flexibility to meet the needs of Indian OEMs. The company’s strategic focus on localisation is helping reduce reliance on imports, thus supporting India’s Make in India initiative.

“We are committed to ensuring that our transmission systems not only meet global standards but are also tailored to the specific needs of the Indian market,” says Iyer. “Our extensive product range and local manufacturing capabilities allow us to deliver high-quality transmission solutions that improve the performance and longevity of construction equipment.”

Bonfiglioli India, a global leader in drive technology, has embraced the green economy by developing transmission solutions for electric and hybrid construction equipment. The company has pioneered electric motor drives for material handling and hybrid machines, helping OEMs reduce emissions and improve energy efficiency.

Kennady V Kaippally, Country Manager and Director, Bonfiglioli India, states, “With the Indian government’s push for faster infrastructure development, there is a growing demand for specialised construction equipment. We are proud to be a part of this growth, offering innovative transmission solutions that cater to the needs of electric and hybrid machinery. Our products not only enhance the performance of construction equipment but also contribute to a more sustainable and environmentally friendly future.”

In line with this commitment to sustainability, Bonfiglioli has recently made significant investments in its Cheyyar facility in Tamil Nadu, with plans to expand its product portfolio for the construction equipment market. The company’s range of planetary gear systems for track, wheel, and slew drives is increasingly being adopted across various segments of construction machinery.

Intelligent, green, and efficient

Looking ahead, the future of transmission systems in construction equipment lies in intelligent technologies that drive efficiency and performance while minimising environmental impact. As the demand for electric and hybrid construction equipment increases, transmission systems will need to adapt to handle the unique requirements of these machines. Smart sensors, predictive maintenance, and condition monitoring systems will continue to play a key role in improving equipment reliability and extending lifespan.

Moreover, with the push towards sustainability and green construction, manufacturers will increasingly focus on designing transmission systems that not only deliver power but also contribute to reduced emissions and energy consumption. Innovations in regenerative braking, energy recovery, and advanced motor drives will pave the way for a more sustainable construction industry.

The role of transmission systems in the construction industry cannot be overstated. From enhancing the efficiency of equipment to ensuring their longevity, these systems are integral to the success of every construction project. As the industry evolves, companies like PowerBuild, Schaeffler India, Bonfiglioli, and others are leading the charge with innovative, efficient, and sustainable transmission solutions that are helping construction equipment meet the challenges of the future. Whether it's powering hybrid machines, enabling automation, or improving energy efficiency, transmission systems are set to play a pivotal role in the ongoing transformation of the construction industry.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com