Continental to present new solution for agri, construction machinery

At Agritechnica in Hanover, Continental will be presenting exhaust aftertreatment solutions for agricultural and construction machinery. Continental?s solutions are designed to conform to the upcoming EU Stage V emissions standards. Continental?s exhaust system sensors, selective catalytic reduction (SCR) dosing modules and metallic catalyst substrates provide the basic components for a highly efficient overall system.

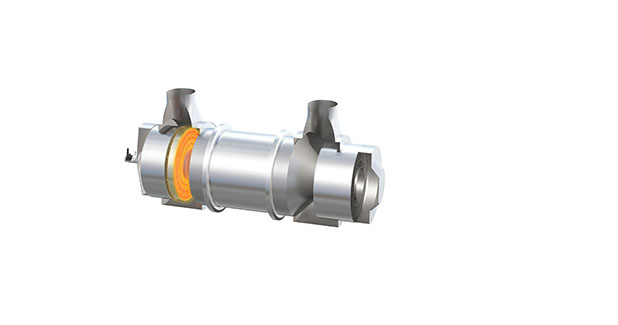

Metallic catalyst substrates with customisable, easily integratable oval or even asymmetrical geometries allow the catalyst system to be mounted directly on the engine. Continental will also be displaying the ring catalyst, which makes it possible to achieve a highly integrated design, in which the entire aftertreatment system, including the SCR injection system, is housed in a single box. These two strategies ? direct mounting on the engine and use of a standardised box ? not only ensure efficient emissions reduction but also make it possible to cater to as many different vehicle applications as possible. In the agricultural and construction sectors, engines are fitted in a wide variety of vehicle types, and production volumes are usually small. For each of these applications, the aftertreatment system requires individual validation and certification. Cost savings are just one of many advantages if an aftertreatment system can be used across a wide range of applications.

?The more compact the aftertreatment system is, the more easily it can be integrated in multiple applications,? said Rolf Br?ck, Head of the Catalytic Converters product line in Continental?s Fuel & Exhaust Management business unit.

Metallic catalyst substrates with customisable, easily integratable oval or even asymmetrical geometries allow the catalyst system to be mounted directly on the engine. Continental will also be displaying the ring catalyst, which makes it possible to achieve a highly integrated design, in which the entire aftertreatment system, including the SCR injection system, is housed in a single box. These two strategies ? direct mounting on the engine and use of a standardised box ? not only ensure efficient emissions reduction but also make it possible to cater to as many different vehicle applications as possible. In the agricultural and construction sectors, engines are fitted in a wide variety of vehicle types, and production volumes are usually small. For each of these applications, the aftertreatment system requires individual validation and certification. Cost savings are just one of many advantages if an aftertreatment system can be used across a wide range of applications.

?The more compact the aftertreatment system is, the more easily it can be integrated in multiple applications,? said Rolf Br?ck, Head of the Catalytic Converters product line in Continental?s Fuel & Exhaust Management business unit.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com