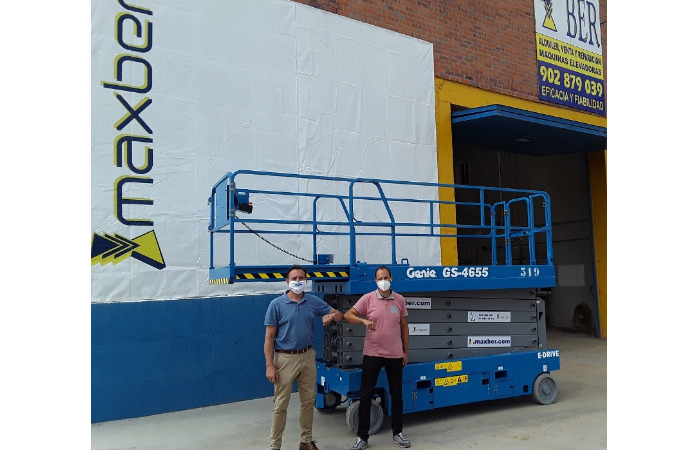

MAXBER receives Spain’s first Genie GS-4655 scissor lifts

The Spanish rental company MAXBER received two Genie® GS™-4655 slab scissor lift. Compact, lightweight and equipped with the latest generation of heavy-duty, front-wheel alternating current (AC) E-drive motors, this eco-friendly machine complements the MAXBER fleet as an ideal solution for today’s increasingly high warehouse, narrow-aisle access applications.

Offering an indoor working height of 15.95 m (51 ft 9 in), thanks to the Genie Smart Link™ Dual Zone control system, the new Genie GS-4655 scissor lift can also work outside up to 8.55 m (27 ft 6 in), which increases its versatility. Only 1.40 m (4 ft 7 in) wide, the GS-4655 is ideal for narrow-aisle job sites, and at a weight of just 3,700 kg (8,160 lbs), this unit is also the solution for work on sensitive, load-restricted slabs and floors. Its low weight also offers the advantage of reducing transport costs. A gradeability of 25 per cent and a break-over angle of 14° provide the ability to climb steep slopes as well as ramps, making transport easier.

Providing a horizontal outreach of 1.22 m (4 ft) with a fully rolled-out deck extension, the Genie GS-4655 scissor lift offers a 350 kg (770 lb) lift capacity for up to three people, allowing them to work in comfort on the platform together with their tools and materials.

Bernardo Gomez, CEO, MAXBER says: “At MAXBER, we are strong believers in innovation and continuous improvement. We always aim to be at the forefront in terms of offering our customers innovative product solutions that use today’s latest technology… and the Genie GS-4655 scissor lift is one of them.”

Equipped with the latest generation of fully-sealed AC E-Drive motors, the Genie GS-4655 scissor lift is designed with sustainability, green productivity and low cost of ownership in mind. Delivering the height and emissions-free power to work indoors and out, it is engineered to work productively, even in harsh outdoor jobsite conditions. Additionally, thanks to its new AC system, which replaces traditional hydraulic drive motors, this model relies on less hydraulic service points, reducing service time and costs, as well as making it cleaner and greener to operate.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com