Ready for the Big Boom

Mass concreting is expected to be a major constituent of upcoming infrastructure projects in roads and highways, railways, sea ports, airports, power plants (thermal, hydro electric and nuclear), irrigation and urban modernisation sectors. High capacity concrete batching plants will be required to cater to these mass concreting demand. ?As far as concrete plant business is concerned, there is a misconception that running a concrete plant is a tedious activity, but we feel that if the end user considers long term operation and while buying a plant if he checks with the reliability, performance, maintenance and productivity for the duration of the project and selects a proper plant, it may be higher investment during buying but higher savings in long term, and this savings may be much more than the initial investment. We also feel that the plants availability should be more than 95 per cent and the proper plants should operate with zero breakdowns for at least two years and this can be assured from a reputed manufacturer only.? points out Rajesh Kawoor, Vice President - Sales and Marketing, Simem Construction and Environmental Engineering P Ltd.

Market Size

The estimated population of existing high capacity batching plants in the country is around 1,000 units, according to the available information. The market had been stagnant at 5-10 new units per year during the lean period. However, now that ?Green Shoots? (popularly termed by the industry) are visible in the country, the business has started moving slowly and is expected to grow steadily, depending on the actual progress on ground.

?Currently, the size is roughly around 40 units and this quantity is expected to increase only when more number of hydropower projects and road projects are announced,? reflects VG Sakthikumar, Managing Director, Schwing Stetter Sales and Services Pvt Ltd. ?As per the current trend in the industry the quantity of plants with 120 cum/hr and above should be floating between 10-15 units. We expect that the quantity will remain the same for next one year. However, we expect the quantity to increase to 15-20 units in the next couple of years and about 30 plants in next five years,? comments Kawoor.

Growth drivers

To begin with, it is important to note that almost 50 per cent of concrete is attributed to realty construction, the single biggest consumer and balance requirement is shared across all other infrastructure segments. However, deployment of high capacity batching plants in this sector is miniscule in number.

Concrete batching plants of capacity 70-90 cu m per hour and above are appropriate for large or mass concreting applications required in dams, barrages, power, concrete road, airport, sea ports, canal lining and such other projects. Indian government?s numerous initiatives to develop infrastructure in all these sectors will drive the demand for such high capacity plants, in the near and distant future.

Upcoming projects in hydro power: Tawang II, Tulvar Stage III, Mukeran III, Anjaw, Attunli, Dibbin, Dinchang, Emini, Talong, eleven projects in Arunachal Pradesh and four Indo Bhutan hydro projects namely Chamkarchu, Kholongchu, Bunakha and Wangchu to be constructed in Bhutan are the expected growth drivers in this sector. The demand growth will be led by roads and highways. India?s drive to build 30 km of roads per day. 10,950 km road projects targeted for award by end of this fiscal; allocation of Rs 81,114.59 crore for highway development; 100 new concrete road projects; Sagarmala project and the government?s determined efforts to increase PPP and BOT awards.

Similarly, in the irrigation sector, Krishi Sinchayee Yogna (PMKSY) outlays Rs 50,000 crore in five years; Ken-Betwa river linking project revived, development of inland waterways; many aided irrigation projects by World Bank (5), Asian Development Bank (4), Japan International Cooperation Agency (11) for many states under consideration by Ministry of Water is likely to drive the growth.

In the airports space, Airport Authority of India is aiming to add 200 new airports by 2030, significantly the controversial new international airport at Panvel near Mumbai and up gradation of the existing will significantly drive this business. Nearly 35 projects worth around Rs 50,000 crore are in the pipeline for investment in the port sector under public-private-partnership (PPP) model and Sagarmala Project related roads and ports sector, along with Make in India movement for increased transportation and freight movement will also contribute their share to the market.

Overall prospects look promising.

Role of software

Schwing Stetter India is probably the only company in India who have an in-house electronics and automation department. ?This department is involved in design and production of control panels for our truck mixers, concrete pumps, batching plants and so much more. Because of the in-house expertise available, with a vast experience of over 17 years in India, we are able to quickly respond to the customer needs and feedback on our equipment. For the high end batching plants, we will introduce our New MI550 control system. This control system will come with an automatic calibration facility for all weighers, silo changeover possibility during operation, accurate manual consumption, schedule based batching, maintenance scheduling, all kinds of statistical reports, SMS facility giving critical alarm on production quantity, PID (Proportional Integrated and Derivative Control) based batching operation, auto batch power recovery mode, authorising based password control, plant networking, etc. This control system can also be integrated with weigh bridge measurements, and GPS facility,? says Sakthikumar.

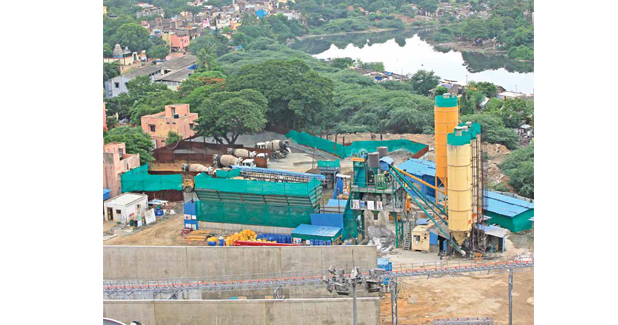

Pollution control

Since all such equipment process aggregates, statutory clearance from the Pollution Control Board is mandatory for all batching plant installations, irrespective of urban, brown field and green field project locations. Supreme Court has very recently issued directions that compliance to environmental norms is extended to all construction equipment. Further, dust and water pollution also cause severe problems to the nearby inhabitants. As such, pollution compliance features are a must in batching plants.

?In developed countries, the Pollution control board addresses the issue of the batching plant site to restore the land to its original condition after the plant is shifted to another site. In such a situation, a plant which is mobile and does not change the site condition will be very useful. Similarly, the recycling plant also plays a major role to make sure the waste concrete is not dumped or thrown which can contaminate the groundwater quality in the neighborhood,? mentions Sakthikumar.

He further elaborates, ?Once the plant is designed to give maximum output per batch and also uses minimum power to give a homogenous mix in a short time, it helps us to save so much on the power. So, our Stetter plants are designed to meet these standards whereas many plants available in the market do not consider the cost of production as the main criteria. We also supply Recycling plant RA12 where the waste concrete can be recovered and used once again in the batching plants thereby protecting the environment and further saving of cost. The components what we use in the wear and tear part lasts very long thereby giving the customer little wear cost during the operation.?

?As the need of pollution control is increasing, we feel that the plant manufacturers should pay more attention in designing the plant so that the pollution is at its minimum. The manufacturers should target to suffice the highest pollution control norms which may come in force in the future. Also the buyer should take an initiative to opt for proper covering for the plant to suppress pollution,? says Kawoor.

Conclusion

In the recently concluded Excon 2015 at Bengaluru, large number of equipment manufacturers showcased similar technology developments, software capabilities, focus on energy conservation, productivity and pollution control features in their large capacity plants. They also feel that business is round the corner and they are ready to meet the upcoming demands from various infrastructure projects.

?Market for high capacity batching plants is expected to increase only when more number of hydropower projects and road projects are announced.?

Equipment Selection Tips

- Correct Plant Configuration

- Adequate Mixer capacity

- Number of Aggregate Storage Bins

- Aggregate feeding conveyor system

- Number of Cement Silos

- Cement feeding to silos

- Accessories for Silos

- Separate arrangement for Micro Silica

- Guarantee for spare and wear parts

- Energy consumption per m3 concrete

- Pollution Control features

- Software capabilities

- Cost of Installation

Factors effecting productivity

- Quality of O&M crew

- Plant orientation and layout

- Safety precautions

- Design mix quality

- Cleaning after use

- Consistency of aggregate size

- Controlled delivery time

- Quality maintenance

- Ensure readiness to receive concrete at site

- Concrete distribution arrangement

- Proper Compaction

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com