Realising the mining potential

India has emerged as one of the major global mineral producers. This was achieved due to the burgeoning demand for raw materials for sectors like power, steel, fertiliser, atomic energy, etc. The increase in metallic minerals is primarily due to the increase in the export and hike in domestic consumption of iron ore. Also, since 2004-05, there has been a hike in non-metallic minerals due to the expansion of cement plants and the rise in production of Pb-Zinc from the mines of Hindustan Zinc. Growth in fuel minerals, though, is still not substantial, despite the increased demand for coal and lignite for power plants both under expansion and ready for commissioning. In turn, the import of coal for steel and power plants have increased manifold.

Rapid economic growth witnessed in China and India in recent decades, has driven the global demand for base metals, steel and speciality metals. It is mainly due to their growth of infrastructure, the manufacturing sector and a large consumer base. This will lead to a spurt in the exploration activities of these metals, especially in precious metals, rare earth elements and lithium.

Speaking about the current scenario in mining, AM Muralidharan, President, Volvo CE had this to say, ?Though coal mining is going fine, it is going at a slow pace and needs to speed up drastically. Iron ore mining on the other hand, has been totally affected, especially in places like Karnataka, Orissa and Goa. We expect the Karnataka operations to get back on its feet slowly and reach a level of 30-40 per cent of what it was in 2011. Mining in Orissa is at a slow pace and in Goa it has completely stopped due to environmental and mining lease issues. Mining in the country, except coal, is currently at 50 per cent productivity level. Growth is expected to come back to 2011 levels, subject to lease agreements going through.?

Says Rajesh Nath, Managing Director, VDMA India, ?For the past few years, global economic uncertainty combined with political upheaval, has made the mining sector volatile where the demand for metals, natural resources and commodities has ebbed considerably. Then again, India has an estimated $200 billion of as?-of-yet untouched mineral reserves. More than 80 mineral commodities are produced here and India ranks among the world?s leaders in iron, bauxite, zinc and coal.?

Rajesh adds, ?The Indian mining market holds large potential for German manufacturers because of the degree of mechanisation. During the last five years, the total import of mining equipment to India developed from ?0.12 billion to ?0.42 billion in 2010, and rose again to ?0.78 billion in 2012. Germany?s share was a near constant one, fluctuating between 63 and 75 million. Hastening disinvestment of public sector units, ensuring coal supplies to the power sector and promoting competition in the mining sector would be some positive development in the mining sector.?

According to him, the Indian economy will see a turnaround in the coming quarters, on account of various steps taken by the government to spur growth. He says, ?German investors in India take a positive long-term view of the Indian market and continue to invest in their operations to tap growth opportunities. Maharashtra, with around 39 per cent share of German investments, remains the most attractive destination; Pune has lately become quite popular, too. Karnataka and Gujarat are other important destinations. Until the market conditions improve, the German companies presently in India are focussing on services and value addition; this includes maintaining existing machinery, streamlining operations and saving costs. They are increasing the local procurement and limiting imports to essential and critical parts only.?

Crawler excavators

Samir Bansal, General Manager ? India, Off-Highway Research, says that the crawler excavator is a versatile product that has applications in all types of construction and mining activities, and therefore, it is very difficult to arrive at a consensus figure on their distribution. During their working life, machine applications may also vary from time to time depending on the work requirements and the nature of the project. Rentals remain the most important end-use segment for hydraulic excavators, and it is estimated that nearly 47 per cent of the active machine population is deployed in this sector.? Samir states, ?Quarry operators and aggregate producers (including sand, stone, granite, marble and limestone) account for 19 per cent of the total population, followed by road contractors, with a contribution of 11 per cent. The excavators bought by the land develo?pment contractors and companies are estimated to be at around eight per cent. The coal and metal mining segment, which invariably uses larger machines, accounts for seven per cent of the machine population and the irrigation contractors? contribution stand at six per cent.?

Speaking about the technology trends in excavator segment, Samir says, ?A very significant point to note is the varying levels of technological sophistication in excavators that are currently being promoted. This varies from basic technology to the latest generations of machines from Caterpillar, Hitachi, Kobelco, Komatsu and Volvo, and further varying levels of technology in between. Contemporary machines have electronically controlled engines, electronic monitoring and control systems with automatic mode selection. They are fitted with efficient hydraulic systems, which results in higher breakout forces, faster cycle times and greater fuel efficiency.?

Technology trends

As a global phenomenon, the pace of technological change had been especially rapid in the second half of the last century and the mechanisation of unit operations has led to the development of long-wall technology, with the concept of mass production in the coal mining industry. This was also aimed at reducing the number of accidents, drudgery, monotony and dangers to workers engaged in underground mining operations. The development of mass production technology including long-wall equipment, continuous miners, ploughs and shearers, has been accompanied by a series of incremental and innovative developments in roof-supporting practices. When India is geared up to open up new mines on the PPP model to adopt mass production technology, the coming years will see the adoption of some of the best technologies in the world.

In the non-coal mining sector of metallic, non-metallic and atomic minerals, production is on the rise since the last decade. The most significant achievement has been the opening up of a new UCIL surface uranium mine near Jamshedpur. The one- time low production iron ore mines which had a capacity below one million tonne, have jacked up their production many times over through the introduction of hydraulic excavators with dump trucks of higher capacities, and mobile crushing systems. Producers like SAIL, TISCO and NMDC continue to replace low capacity rope shovels and dump trucks with upgraded versions.

Says Rajesh Nath, ?Mining depths in Indian coalfields are quite shallow, except for a few mines in the Jharia and Raniganj coalfields. The major share of coal resources lies at a depth of less than 300 m. About 87 per cent of coal resources lie within the depth range of 600 m. However, exploration work beyond 600 m depth is yet to be taken up in most of the coalfields. It is expected that the resource figures will improve considerably, with increased depth of exploration.? According to him, opencast and underground mining are the popular mining processes in India. Opencast mine production grew by 2.12 per cent to 488 mt in the year 2011-12; in the case of underground mines, the production in 2011-12 was 51.96 mt.

Rajesh Nath further adds, ?In the case of mining equipment, the technology depends on the mining operations in the country. In India, opencast mining is more popular than underground mining. Hence, regarding the equipment required for opencast mining, like dumpers, dozers, shovels, draglines and excavators, the level of technology of the equipment manufactured is at par with international standards. German manufacturers and VDMA mining equipment do a lot to retain the leading position in mining technology, especially in underground mining, and also in safety technology.? He further adds, ?Many German companies are planning more investments in India. In the construction equipment and building machinery sector as well as the mining machinery sector, companies like Liebherr, Beumer, Wirtgen, Caterpillar, Putzmeister, Hess, BHS, to name a few, have invested substantially in the last few years.?

In the prevailing situation, the mining sector is facing tremendous pressure to control production costs without compromising on the essence of environment-friendly operations. This has necessitated a perceptible towards modern mining equipment. Technology will continue to play a vital role in maintaining desired productivity levels and in supporting the concerns of environment-friendly mining. We are already witnessing to technology changing the way the mines operate today; today, there are large surface coal and iron ore mines in India which use state-of-the-art equipment. The underground base metal mines have chalked-out programmes for modernisation and are using high-end mining equipment and methods like drilling, rock bolting, mucking and hauling.

Throwing light on the growth prospects for the bulk handling equipment for the mining segment, Y Srininvas Reddy, Managing Director, Bevcon Wayors says, ?Projections of demand?supply at current levels are very unpredictable and ambiguous; this is because nearly Rs 10 lakh crore worth projects are stalled for want of governmental clearances. Unless clarity exists on these projects, we can`t forecast anything. However my perspective is, the impact on growth was down around ten per cent.? He then adds, ?Then again, in spite of the current complex situations prevailing, Indian bulk material handling has a very bright future as per the 12th Plan i.e, 2012-2017. Investments in infrastructure are going to be nearly ten per cent of the GDP. If this planned investment is realised, it will propel the economy onto a higher trajectory, which will lead to abundant business opportunities for the bulk material handling sector, since it is a key contributor to infrastructure growth.?

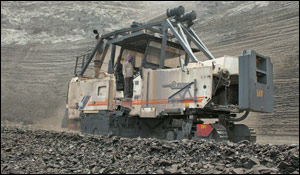

Surface miners

Coal mining in India has laid much emphasis on surface mining, together with huge investments by Coal India in some of the mega projects. While underground production is stagnating, production from surface mines is on the rise. The thrust on surface mines has also significantly enhanced the mine production capacity through infusion of millions of rupees in large capacity mining machinery and material handling systems.

The application of surface miner technology involves extracting medium hard minerals by taking advantage of the higher efficiency of continuous excavating. Extracting of a ?run of mine? product in one step, which makes at least the primary crushing stage dispensable, eliminates the hazards of blasting and the environmental impact, while extracting the valuable minerals in a selective manner for higher efficiency in the processing plant. The Wirtgen Group today has the widest range of surface miners which are used in many parts of the world on different applications.

Says P Ramesh, Managing Director and CEO, Wirtgen India, ?There is a slowdown in the market, and consequently in the surface mining sector; there are a number projects being stalled due to environmental clearance. However, we expect the surface mining segment to pick up by the middle of next year.? Ramesh added, ?The demand for surface miners has been cyclic but acceptability has increased considerably in last ten years, both for limestone and coal. Around 25 per cent of coal which is mined in India is done with Wirtgen surface miners. Wirtgen have been pioneers in the design and manufacture of surface miners worldwide and we have a 80 per cent market share in India.?

Need of the hour

Muralidharan says, ?The need of the hour is for the government to release mining leases for iron ore, change or amend environmental policies and allocate more coal blocks and coal mining to private contractors, in order to increase productivity and reduce the import of coal.? Despite the opening up of the mineral sector for hundred per cent FDI since February 2000, there has not been much inflow of investment, domestic or foreign, in the exploration and mining sector. To make matters worse, the mining industry in India, with its 52 per cent tax rate, is the highest taxed industry in the world. All this calls for urgent rationalising and reducing of royalty rates and corporate taxes, as well as bringing about necessary amendments in the Mines and Minerals Development and Regulation Bill 2011 to make it more investor-friendly. Most importantly, providing a simple and transparent mechanism for the grant of mining leases or prospecting licences through competitive bidding will definitely boost growth prospects.

| Sectoral off-take of raw coal (million tonne) | |||||

|---|---|---|---|---|---|

| Companies | Achieved (2011-12) | ||||

| Power | Steel | Cement | Others | Total | |

| CIL | 301.5 | 11.5 | 7.28 | 56.6 | 376.89 |

| % | -80 | -3 | -1.9 | -15.1 | -100 |

| SCCL | 39.9 | 1.1 | 5.6 | 4.9 | 51.5 |

| % | -77.5 | -2.1 | -10.9 | -9.5 | -100 |

| Others | 25.25 | 3.4 | 0 | 7.7 | 36.34 |

| % | -69.5 | -9.4 | 0 | -21.1 | -100 |

| Total | 366.65 | 16 | 12.88 | 69.2 | 464.73 |

| % | -78.9 | -3.4 | -2.8 | -14.9 | -100 |

| New mines planned by SCCL in XIIth Plan | |||||

|---|---|---|---|---|---|

| Sl. no. | Mine | Year of Opening | Capacity (LT) | ||

| 1 | Adriyala | 2011-12 | 28.1 | ||

| 2 | JVROC-2 | 2012-13 | 40 | ||

| 3 | RKPOC-I | 2013-14 | 25 | ||

| 4 | Abbapur OC | 2013-14 | 6 | ||

| 5 | Kistaram OC | 2014-15 | 20 | ||

| 6 | Jallaram OC | 2014-15 | 22.8 | ||

| 7 | Jangedu UG | 2014-15 | 8 | ||

| 8 | Khairagura UG | 2014-15 | 10 | ||

| 9 | Kasipet ? 2 UG | 2014-15 | 5.4 | ||

| 10 | KK6&7 | 2014-15 | 8 | ||

| 11 | KKOC | 2016-17 | 17.5 | ||

| 12 | IKOC | 2016-17 | 12 | ||

| 13 | Mahadevapur OC | 2016-17 | 10 | ||

| 14 | Peddapur | 2016-17 | 10 | ||

| 15 | KTK-9 UG | 2016-17 | 27 | ||

| 16 | Reconstruction of existing UG mines | 2012-13 | 3 | ||

| New projects under CIL | |||||

|---|---|---|---|---|---|

|

© 2026 EQUIPMENT INDIA - ALL RIGHTS RESERVED  +91-22-24193000

| +91-22-24193000

|

Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com

| |||||