Rolling innovations

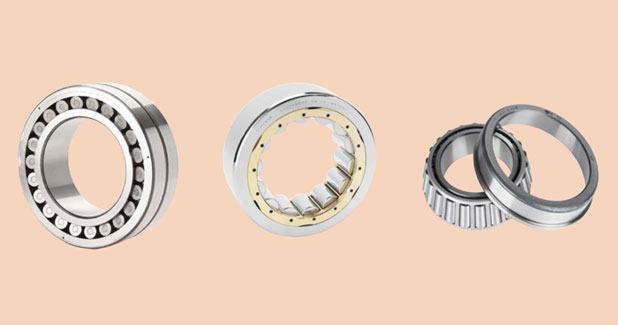

Bearings for construction and mining applications have seen innovative developments in the recent times. With the construction and mining equipment market is growing, the momentum of innovation in bearings is to pick up in the coming days. <br /><br />The construction equipment market is back on track with a double-digit growth expected in the coming years. This is expected to boost the business prospects of bearings in future. Construction and mining equipment require bearings with certain degree of ruggedness that is different from a passenger vehicle, because these equipment are used in harsh environments, where there is a risk of contamination from dust, mud, and huge loads. We explore the bearings market for construction and mining equipment, the market scenario, types of bearings, new products and solutions and market outlook. <br /><br /><span style="font-weight: bold;">Bearing types</span><br />There are various types of bearings available in the market today depending on their scope of applications in the industry. The selection of these bearings for a specific application or equipment will depend on the type of job the machine is performing. <span style="font-weight: bold;">Sanjay Koul, Chairman & Managing Director, Timken India</span>, elaborates, "Depending on the application, the widely used bearings of Timken include tapered roller bearings, spherical roller bearings, and cylindrical roller bearings for power transmission parts. Slewing bearings are used for any swing movements with hinges to help reduce friction. Ball bearings are used for auxiliary applications like lubrication pumps-motors."<br /> <br />Says <span style="font-weight: bold;">Kaustubh Vasant Phadtare, Managing Director, Kavitsu Group of Industries,</span> "Generally, the selection of bearings depends on the load carrying capacity of the application. In case of heavy loads, three row roller bearings are suitable, whereas for medium to light loads, ball bearings are suggested."<br /><br /><span style="font-weight: bold;">Mitul Dave, Managing Director, CCTY Bearing India,</span> explains, "Rolling and sliding bearings are found throughout construction and mining applications. Hydraulic cylinders, axles, gearboxes, articulation joints, suspension systems, booms, linkages and steering systems require movement, which is where you will find bearings." <br /><span style="font-weight: bold;">Ramnath Shenoy, Executive Director, NTN Bearings India,</span> elaborates on the type of bearings offered by his company, "We offer a large range of products for the construction and mining sector. These include spherical, taper and cylindrical roller bearings. We also have specialised products such as NTN's ULTAGE series, sealed spherical roller bearings, large size and dust-cover type bearing units, and triple lip sealed bearings for conveyor systems.<br /><br /><span style="font-weight: bold;">Market scenario</span><br />Bearings for CE applications constitute a smaller share compared to other industry segments and automotive sector. However, with the construction equipment market is growing a faster pace, the bearings market is also positive on a proportional growth for bearings that find application in construction equipment. On the bearing market scenario, Koul says, "The overall bearing market size is about Rs 100 billion, of which, the industrial, automotive sector is estimated to be around 52:48. The construction, mining and material handling equipment application would constitute 8-10 per cent of the overall market with limited information on aftermarket usage."<br /><br />Shenoy says, "We estimate the market for bearings in India at about Rs 95 billion. Of this, about 40 per cent is estimated as industrial usage. The demand for construction, mining and material handling equipment should be about 4-5 per cent of industrial demand."<br /><br /><span style="font-weight: bold;">Bearings for different applications</span><br />Bearing companies offer a range of products for different applications in construction, mining and material handling equipment. Says Phadtare, "We are developing slew gearboxes which can accompany slew bearings. These will be hydraulically driven. Also, transit mixer gearboxes are under development and will be ready by this year end. Scheduled maintenance of the dust seals and lubricating grease should be carried out to ensure long life performance of the bearings."<br /><br />Koul explains the features of Timken bearings for different applications, "For shovels, Timken improved the performance of swing gear drives by extending the lower swing shaft service life. Without changing the housing dimensions or overall package width, Timken designed a bearing that allowed a larger shaft diameter to reduce stress concentrations and improve shaft life. Customers report one-and-a-half to three times increase in shaft life." He further adds, "Haul truck wheel ends benefit from Timken tapered roller bearings, which offer high load-carrying capacity in a compact envelope. Through advanced surface coatings and finishes, these bearings also provide greater debris resistance and longer bearing life. Many mine operators choose Timken debris-resistant bearings, which last up to 3.5 times longer than Timken standard options."<br /><br />Dave elaborates, "We have several new products for the construction market. We offer single- and double-row full-complement cylindrical roller (RN/RNN) bearings for planetary gearboxes and wheel ends. Our RN/RNN bearings have a compact design, low noise and vibration, optimised crown profile for rolling elements and surface treatment options for improved performance." CCTY engineers have also developed new, high-performance self-lubricating bushings for tie rods and linkages, steering control systems, booms and arms. These products offer long life and low wear. <br /><br />Dave adds, "The Square Ball Universal JointTM is a product that is getting a lot of attention. It is a new take on the century-old design. By reducing the number of components of 100 down to just eight, the square ball design provides a smoother rotation and no tolerance stack up. It is intended for intermittent applications such as steering systems and joystick operations on construction walk-behind vehicles."<br />On the importance of long life performance, Dave elaborates, "In order for bearings to handle a lifetime of heavy loads, vibrations and potential containments, they need solid construction. It all begins with the right design. Bearing experts who review application requirements can verify that the bearing will have a long life, or find alternative bearing solutions that can extend the life." <br /><br />According to him, proper lubrication, bearing shields/boots and the ability to handle high temperatures and heavy loads all factor into the bearing's life. Dave points out that bearings used in harsh environments also require the manufacturer to use the following: <br /><br /><span style="font-weight: bold;">High-quality steel: </span>Steel with a fine grain and low non-metal inclusion should always be selected. Look for a manufacturer that is ISO9001 or TS16949, like CCTY Bearing. These manufacturers inspect incoming steel to insure that it meets internal standards. <br /><span style="font-weight: bold;">Traceability:</span> Bearing manufacturers should be able to trace an end-product to the steel lot. This shows that they are able to maintain control throughout production. <br /><span style="font-weight: bold;">Process control: </span>In order to verify that every product meets established standards, strict controls and inspections must be in place. Advanced product quality plan (APQP) procedures, ISO/TS 16949 certification, automation and on-site testing maintain precision production.<br /><br />Shenoy states, "NTN's ULTAGE Series are our special products for this sector in response to their demand for performance under harsh operating conditions. ULTAGE spherical roller series are engineered to work under extreme operating temperature of 200<span class="st">°</span>C and at the same time have the highest load carrying capacity in the industry. They also support much higher speeds than the conventional type of spherical roller bearings. Our ULTAGE range in taper and cylindrical roller bearings is also being expanded."<br /><br />He adds, "As compared to standard bearings, NTN ULTAGE series offers five times more life and higher limiting speed in such harsh conditions. We have other features like compact design, higher load capacity, ease-of-use in mounting and longer service life while contributing to more eco-friendly operation."<br /><br /><span style="font-weight: bold;">Lubrication-free bearings</span><br />The concept of lubrication-free bearings or maintenance-free bearings was emerged where long bearing life was required without maintenance. Says Phadtare, "Lubrication-free bearings is just a concept in which the lubrication is done at the assembly stage. Though the life of the bearing will depend on how well it is used. The lubrication used is on a higher side and generally isn't preferred by the customers. We do not suggest lubrication-free bearings in harsh environment."<br /><br />According to Koul, lubrication is a very important aspect for any two rolling surfaces. "It reduces friction, dissipates heat and weeds out any particles. The right lubricant and lubricant delivery systems can help extend bearing life, protect equipment, reduce costs and keep operations running efficiently," he states on the importance of lubrication. On lubrication-free bearings he adds, "Lubrication-free bearings are made with a super-finish, specialised material (which acts as a lubricant) and intended for specific applications. The sealing also plays an important role. Some special applications use the running medium such as pneumatic and mud as lubricants." <br /><br />Timken Solid Lube bearings provide a lubricating alternative to grease when lubrication is not optimal or when re-greasing is difficult due to accessibility. It is a standard bearing where the free volume between the inner and outer races and the rolling elements are filled with oil embedded in a polymer matrix.<br /><br />According to Dave, all bearings require lubrication. He adds, "Maintenance-free bearings use self-lubricating material on the contact surface to eliminate the need for lubricants like grease or oil. Apart from oil/grease cost savings, this type of bearing increases the machine's operating efficiency as there is no down-time due to periodic - or forgotten - maintenance.CCTY's self-lubricating bearings and bushings have high load rating capacity, temperature resistance, low wear, and low friction." <br />CCTY has a complete range of self-lubricating solutions that include PTFE composite, PTFE fabric and polymer composite. "We also manufacture special bushings for applications that require very low friction and wear, high frequency and high temperature," Adds Dave.<br /><br /><span style="font-weight: bold;">Operational challenges</span><br />In most cases construction and mining equipment operate in challenging conditions where bearings are prone to dust and dirt. Says Phadtare, "In construction and mining applications, the bearings are subjected to harsh conditions such as dust and dirt. These particles enter the raceway of the bearings and start damaging them while rotating with the balls. Thus, scheduled maintenance is of utmost importance if the desired lifecycle is to be achieved."<br /><br />Koul observes, "Construction and mining equipment deal with heavy loads, shock, sudden movement or pressure, debris and tough environmental conditions. Bearings are designed to withstand challenging conditions and add value to operations by significantly reducing downtime associated with moving equipment."<br /><br />Dave elaborates, "Bearings used in construction and mining applications operate in harsh environments. They are subjected to heavy loads, continuous running, shocks and vibrations, and dust and contamination. It is important for OEMs to work directly with bearing manufacturers so that the right bearing solution is chosen. Operational performance in extreme conditions hinges on uptime and functionality, two factors that CCTY Bearing ensures by teaming our bearing experts with OEM engineers at the start of a design or redesign."<br /><br />According to Shenoy, the operating conditions are very severe with high impact load and severe dust or water ingress. "Premature failure could lead to safety issues. NTN ULTAGE series are designed to work under these severe conditions. This is achieved by the superior design and sealing properties of ULTAGE series, the high grade bearing steel from Japan which we use for the same along with special heat treatment process."<br /><br /><span style="font-weight: bold;">Expansion plans</span><br />Bearing manufacturers are constantly working on developing new features and advanced solutions to meet the requirement from customers on various parameters. Phadtare elaborates on his company's plans in this direction, "We are planning to introduce new hardening systems which will ensure that maximum reliability and life is achieved without compromising on quality. We are also researching on new lubricating systems which will extend the life of the bearing further."<br /><br />Says Dave, "We have been manufacturing bearings for more than 20 years, and recently established our Indian sales and engineering office in Vadodara, Gujarat - along with remote teams to assist OEMs in areas from Delhi and Pithampur to Chennai and Coimbatore. We are currently investigating warehouse locations to provide our OEM customers with just-in-time (JIT) delivery." <br /><br />He adds, "India is naturally poised to become a market leader, so it is important for CCTY Bearing to be able to quickly service the growing demand. To do so, our R&D department is constantly engineering new products. For example, the RN/RNN series for planetary gears is now available in India. It joins our Square Ball Universal JointTM and the FSA bushing, a PTFE-fabric lined bushing with for heavy loads and low speeds as the newest extensions of our product line. We are focused on the construction market as our expertise can improve movement in articulation and bucket joints, track and swing drive gearboxes, and hydraulic cylinders. Our spherical plain bearings, rod ends, tie rod assemblies and full bushing line are known for their dependability in severe-duty applications, so we are able to help companies consolidate suppliers while improving margins. Apart from the standard product offerings, our focus is on engineering partnership with OEMs where we leverage our bearing expertise and agility to solve customer problems."<br /><br />On the product expansion and diversification, Koul says, "Timken has diversified its portfolio beyond bearings, adding gearboxes, chain, belts, couplings, lubrication systems, industrial clutches and brakes, and a variety of industrial services to its portfolio to serve the Indian OEMs and end-users with the same quality, brand promise and reliability as Timken."<br /><br /><span style="font-weight: bold;">Market outlook</span><br />According to a Ken Research report, the Indian organised bearings market is estimated to grow at a CAGR of 19.8 per cent over FY 2015-19. The construction equipment market is expected to grow in double digits in the coming years. This is expected to boost the business prospects of bearings in future. Phadtare says on a positive outlook, "The market size of bearings is expected to grow by around 25 per cent by 2020. Demand will increase due to the government programmes such as 'Make in India'. This is helping us to grow as well!"<br /><br />Koul anticipates demand from mining and construction space. He says, "With increasing demand on current coal production from 680 million tonne to 1,000 million tonne by 2020, the market is anticipated to grow at a double-digit CAGR. With the demand for housing, urbanisation and infrastructure push, the construction market is expected to grow accordingly."<br /><br />The outlook is certainly positive for bearings market considering the growth trend in infrastructure development which will perk up the demand for bearings of new improved features. <br /><br /><span style="font-weight: bold;">- Sudheer Vathiyath</span><br />

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com