Kohler introduces KDI 3404TCR SCR compact engine

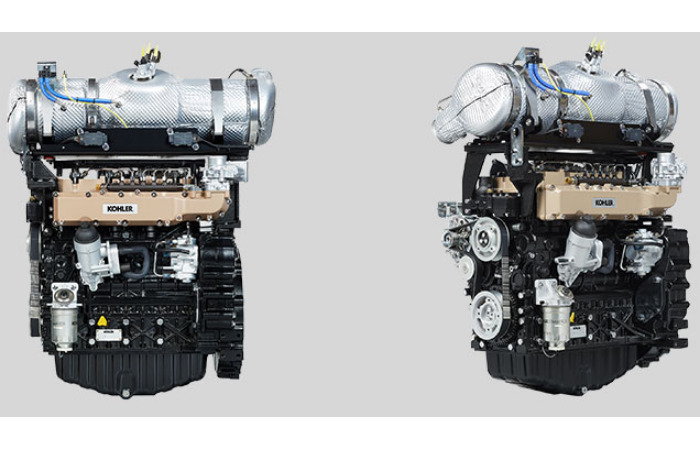

Kohler offers the KDI 3404TCR SCR compact engine with high torque density, making it possible to guarantee performance typical of engines with larger displacement. The KDI 3404TCR SCR engine is suitable for any type of off-road application, offering maximum flexibility of installation and superior performance, according to the company.

The management of the exhaust gas after-treatment system is extremely effective and intelligent, as it is characterised by very long average regeneration intervals and by the ability to regenerate the DPF, mainly in passive mode and in any case without any impact on engine performance or the driveability of the machine.

The KDI engines are designed to have high performance features with extremely efficient combustion, which makes it possible to fully comply with the limits of the strictest emissions regulations.

The exhaust gas after-treatment system of the EU-Stage V versions is housed in a single compact and easy to install module, with flexibility guaranteed by the possibility to customise the layout according to the installation on the machine.

The performance in the EU-Stage V version is even higher, to the point that the KDI 3404TCR SCR engine can reach 112 kW already at 1,800 rpm, thus allowing it to work at low rpm with significant advantages in terms of noise and consumption.

The KDI 3404TCR-SCR offers advantages in terms of performance, size and emissions. It also stands out for its architecture, such as the side power take-offs that flank the main and secondary power take-offs and are designed make the KDI 3404 the ideal solution for manufacturers who want the maximum installation flexibility. Another unique feature of the KDI 3404TCR SCR is the counter-rotating shafts contained in the bedplate architecture, which provide excellent reduction of vibrations, thus guaranteeing operator comfort and the silent operation of the engine.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com