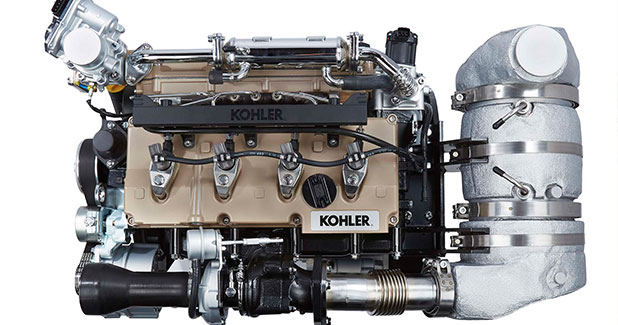

Kohler showcases KDI engines at Agritechnica

Kohler presented its new platform of diesel engines at Agritechnica. These engines are

designed to meet the requirements of a market that demands more application flexibility

and compliance with the various emissions limits, along with performance and

productivity.

Kohler?s Stage V solution is once again ?the game changer? for all machinery

manufacturers with compact design, best-in- class performance, reduced consumption,

easy installation, and optimised solutions for every emissions regulation.

?With the Stage V development, Kohler adds another model to the line-up. KDI engines

are characterised by extremely clean combustion and now, with the introduction of the

DPF, we take full advantage of the efficiency of the combustion to deliver to our

customers the most advanced technology and the most compact aftertreatment system in

the market. We are especially proud of the DPF smart regeneration strategy that we

developed through extensive use of advanced simulation tools and testing. Kohler?s

exclusive regeneration strategy is completely transparent to the end users in every

application and duty cycle,? the company said in a press release.

Kohler released two DPF versions. The first one reaches a maximum service interval of

10,000 hours, whereas the second is the most compact of the market and ensures a

maintenance interval of 6,000 hours, according to the company.

Kohler offers the aftertreatment system mounted on the engine or separate, and thanks to

the 360? rotation of the axial and radial inlet/outlet pipes it provides excellent adaptability

for every application.

Kohler is also extending the KDI engine line-up with new configurations for less

regulated countries. These versions, with a 1,600 bar pressure common rail, no EGR and

no DOC, will ensure the same performance of other configurations.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com