Search

FAE's Largest Remote-Controlled Tracked Carrier Yet

FAE has launched its largest remote-controlled tracked carrier, the 120-horsepower RCPU120. Able to work on slopes as steep as 55 degrees, the RCPU120 can mulch branches, wood, grass, and small shrubs.

Avant Launches Low-Cost Version of Largest Compact Loader

Avant Tecno has launched its 855i articulated compact wheel loader in North America, which boasts the same lifting power and height as its largest, most powerful model but at a lower cost.

Powering Progress

Gensets are vital power sources, offering reliable electricity for backup, off-grid, and industrial applications.

Avant Launches Low-Cost Compact Loader

Avant Tecno has launched its 855i articulated compact wheel loader in North America, which boasts the same lifting power and height as its largest, most powerful model but at a lower cost.

Powering Progress

Gensets are vital power sources, offering reliable electricity for backup, off-grid, and industrial applications.

BICES 2023: Full steam ahead for preparations

BICES will be held on September 20-23, 2023 in China.

Wacker Neuson Introduces Compact ST27 Track Loader

Its the smallest model in its line of compact track loaders.

BICES 2023 conference held during CONEXPO

On March 15, the press conference of the 16th China Beijing International Construction Machinery, Building Materials Machines and Mining Machines Exhibition & Seminar (BICES 2023) was held at CONEXPO-CON/AGG in Las Vegas

BICES 2023 conference held during CONEXPO

BICES is an industrial exhibition in China with the longest history and high-quality performance.

Kioti to finally launch its first CTL and skid steer

Kioti will be formally launching itself into the compact construction equipment market with the release of its first skid steer and compact track loaders in the first half of 2023.

Kioti to finally launch its first CTL and skid steer

Kioti had introduced the brand to its dealers in late 2020

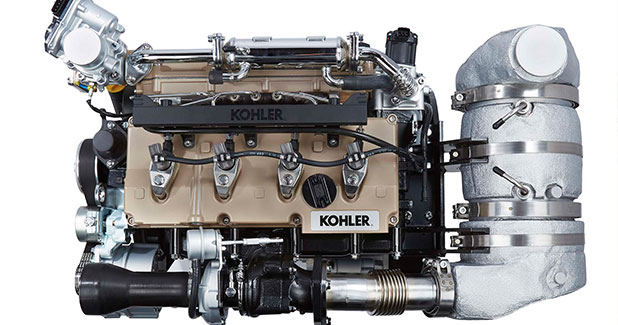

Kohler Engines approves use of HVO for diesel engines

Kohler Engines said it will be using hydrotreated vegetable oils (HVO) in all its diesel engines.

Kohler Engines approves use of HVO for diesel engines

Kohler Engines said it will be using hydrotreated vegetable oils (HVO) in all its diesel engines.

Kohler is now a member of eFuel Alliance

The European organisation represents the interests of companies producing synthetic fuels from renewable energy on an industrial scale.

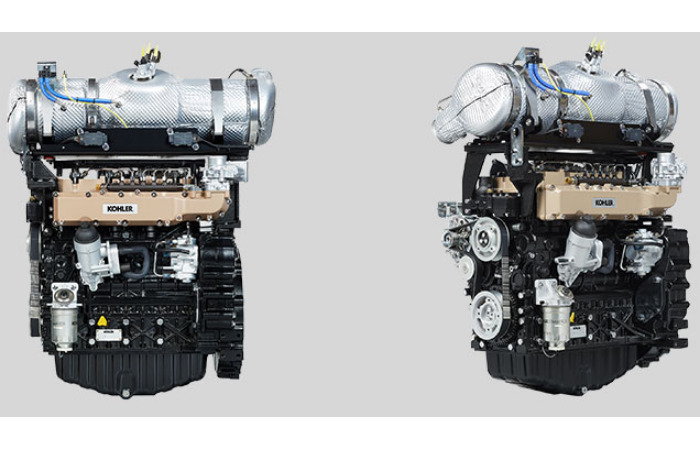

Kohler introduces KDI 3404TCR SCR compact engine

The KDI 3404TCR SCR engine is suitable for any type of off-road application

Lone Star Drills introduces remote-controlled tracked drill

Lone Star Drills has introduced an all-new tracked drill with an automatic SPT hammer for improved accuracy in geotechnical and soil sampling applications.

KOHLER launches PCV680LE engine

KOHLER has announced the launch of the Command PRO EFI propane engine (Model PCV680LE).

Lone Star Drills introduces remote-controlled tracked drill

Lone Star Drills has introduced an all-new tracked drill with an automatic SPT hammer for improved accuracy in geotechnical and soil sampling applications.

Kohler launches CH440DF engine

Kohler Co announced the launch of the Command PRO? dual-fuel CH440DF engine, an addition to the popular Command PRO lineup that construction professionals have come to rely on to power a wide variety of equipment.

KOHLER expands Command PRO engine lineup

KOHLER announced the launch of the Command PRO? dual-fuel CH440DF engine, an addition to the Command PRO lineup that construction professionals have come to rely on to power a wide variety of equipment.

KOHLER expands Command PRO engine lineup

KOHLER announced the launch of the Command PRO? dual-fuel CH440DF engine, an addition to the Command PRO lineup that construction professionals have come to rely on to power a wide variety of equipment.

We have the widest range of oils to meet all requirements

GS Caltex India is a 100 per cent subsidiary of GS Caltex, which is a 50:50 joint venture between GS Energy of South Korea and Chevron Corp of USA.

Allen introduces new walk-behind trowel

Allen Engineering Corporation, a leader in concrete finishing equipment, announced the launch of PRO430E Edger walk-behind trowel.

VECV launches India's first BS-VI CV Range

Eicher Trucks and Buses revealed India's first BS-VI compliant all-new range of Eicher Pro 2000 series of light-duty trucks.

Allen introduces new walk-behind trowel

Allen Engineering Corporation, a leader in concrete finishing equipment, announced the launch of PRO430E Edger walk-behind trowel.

Technology paving the way for innovation

The recently concluded mega construction equipment event bauma saw a slew of new technologies on show that are going to attract the attention of the customers in future.

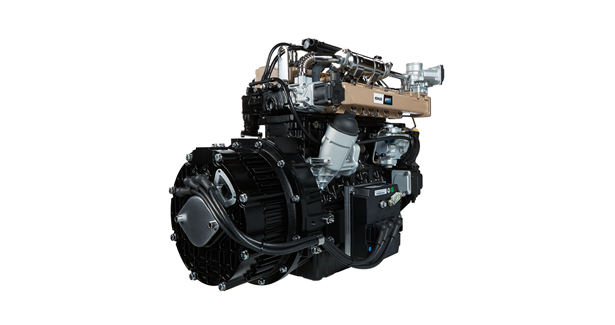

Kohler showcases hybrid solutions at bauma 2019

Kohler exhibited the K-HEM 2504, a hybrid unit generating a combination of electrical and mechanical power consisting of a KDI 2504TCR 55.4 kW diesel engine that complies with Stage V legislation without SCR, and a 48 V electric motor that guarantees 19.5 kW peak power and 9 kW continued power, and maximum safety levels due to the voltage.

Kohler guarantees Stage V certification for entire diesel range

Kohler has reached its latest milestone of Stage V certification for KDI engines in the 19-56 kW power range. Thanks to the exciting partnership with one of the agencies accredited to the European Union for the certification of internal combustion engines, the first half of 2018 was devoted to undertaking thorough tests and analysis on the Kohler range of diesel engines with the aim of verifying their compliance with all the requisites indicated by the legislator.

KOHLER to showcase 5400 Series engines at GaLaBau 2018

The KOHLER 5400 Series will be highlighted at GaLaBau 2018. Designed to bring easy starting and quiet, smooth operation to lawn tractor applications, the new single-cylinder engine line includes models between 17 and 19.5 hp.

Managing risk in a highly competitive industry

With a strong but volatile outlook for the mining sector, the industry is focused on future growth through expanded production, without losing sight of operational efficiency and cost optimisation.

Kohler commands PRO EFI ECH440

The new pump offers enhanced fuel efficiency, greater overall reliability, and easier starting in harsh conditions to a wide variety of equipment.

Kohler commands PRO EFI ECH440

Kohler has introduced the Command PRO? EFI ECH440, the single-cylinder engine that integrates closed-loop electronic fuel injection technology (EFI).

GS Caltex's offerings for Infrastructure Sector

Nearly every business in construction sector is under increasing pressureto lower operating costs and increase efficiency. This often means doing more with fewer people and using equipment for longer duration.

GS Caltex's offerings for Infrastructure Sector

Nearly every business in construction sector is under increasing pressure to lower operating costs and increase efficiency. This often means doing more with fewer people and using equipment for longer duration.

Kohler showcases KDI engines at Agritechnica

Kohler presented its new platform of diesel engines at Agritechnica. These engines aredesigned to meet the requirements of a market that demands more application flexibilityand compliance with the various emissions limits, along with performance andproductivity.

Mine Maintenance a Blast

The new Hydroblaster high-pressure washer is designed specifically for the mining and construction industry.

Kohler Engines to exhibit innovations at Demopark 2017

Kohler will be showcasing its products at Demopark, which will take place in Eisenach, Germany, during June 11 to 13. The product portfolio on display will comprise its award winning innovative diesel engines, including vertical and horizontal gasoline engines, as well as its recently introduced trifuel engines, which highlights Kohler?s great effort in alternative fuels.

ALLEN riding trowel

Allen, a leader in professional quality site prep and concrete finishing equipment, announced the debut of their new HP205 riding trowel. The HP205 is a high performance, twin-engine ride-on power trowel.

Allen introduces high performance riding trowel

Allen a leader in professional quality site prep and concrete finishing equipment, announced the debut of their new HP205 Riding Trowel. The HP205 is a high performance, twin-engine ride-on power trowel.

Engines for Agricultural Applications

The range of KDI engines by KOHLER Engines is already the new technological benchmark for industrial applications in the range of 37-100 kW. The rapid success of this innovative engine solution is the result of engineering choices that meet the specific needs of manufacturers and end users.

High Performance Riding Trowel

Allen Engineering Corporation (AEC) announced the debut of their new HP105 Riding Trowel. The HP105 is a high performance twin engine ride-on power trowel. It is a work horse delivering a total of 53hp and built for concrete professionals.

Kohler Engines: Service 2.0

Having designed the family of KDI engines, technologically advanced and the benchmark for industry standards within the sector, Kohler Engines is implementing sweeping innovations in the field of technical assistance.

Innovations

Kohler Engines Technical ServicesKohler Engines has introduced innovations in the field of technical assistance.Innovative Seal Materials from Trelleborg

JCB Steps up Engine Strategy Development

JCB forges a partnership with the Kohler-Lombardini Group, a leading global manufacturer to produce engines for its compact equipment.JCB has gone from being a new entrant in engine manufacturing to an innovative global producer with the first JCB engine rolling off the production line in the UK in November 2004.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com