Making steel plant productive, efficient and profitable

The steel industry is expected to continue with the present momentum of growth and contribute to the country's economic growth and development. Two such trends from a business and operating standpoint for the steel industry are: achieving excellence through operational optimisation and investment in R&D.

Achieving excellence through operational optimisation

There is continued pressure on steel prices due to capacity overhang and competition from inter-linked global markets. This has made it indispensable for the steel industry to pay critical attention to operational excellence to protect market share and margins.

Deploying advanced technologies is therefore imperative to achieving operational efficiency, leading to product excellence. Advanced technology lubrication ensures maintenance and protectfast output. ion of heavy machines and optimisation of performance, resulting in targeted and

With a portfolio of advanced technology lubricants, ExxonMobil? offers a complete range of lubrication solutions to help extend oil life, achieve energy efficiency and extend equipment life for the metals industry. This also includes OEM approved products with years of proven performance, as well as advanced problem-solving synthetic oils and greases. A few of ExxonMobil's offerings for the steel industry are: Mobilith SHC?Series multipurpose greases are high-performance synthetic lubricants developed to protect equipment in severe applications operating at extreme temperatures. Their excellent adhesion, structural stability and resistance to water make them suitable for use in a wide variety of machinery and components.

Mobil SHC? Polyrex Series greases deliver high-performance lubrication through advanced polyurea thickener technology. Mobil SHC Polyrex Series greases are designed to offer high-temperature performance, excellent water resistance and balanced wear protection for a wide variety of industrial and food processing applications.

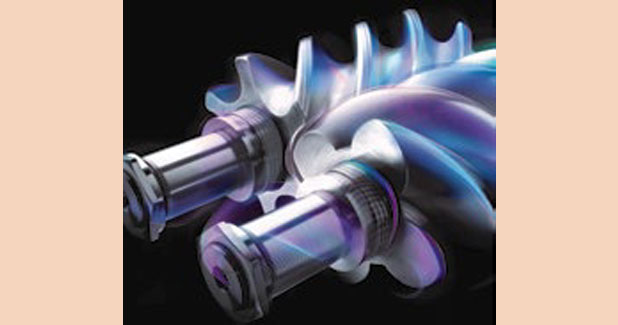

Mobil SHC? Rarus Series synthetic air compressor oils protect vane and rotary screw air compressors. They are designed for severe service - such as high final compression temperatures or extended oil drain intervals - where other synthetic oils do not meet service life expectations.

Mobil SHC Rarus Series synthetic air compressor oils are formulated to deliver up to three times longer oil drain intervals than other synthetic air compressor lubricants. In fact, Mobil SHC Rarus oils have even demonstrated the ability to perform for up to 24,000 hours in field tests.

Investment in R&D

The industry needs to make investments in R&D to identify new solutions and technology to ensure energy efficiency, decrease downtime and smoothen operations. The Ministry of Steel also plans to set up Steel Research and Technology Mission in India to promote R&D activities in the sector.

At ExxonMobil, enormous emphasis is placed on ongoing investment in R&D, working side-by-side with the world's leading original equipment manufacturers (OEMs) to develop the most effective products and maintenance solutions. We intend to grow and invest in programs to ensure and deliver advancing productivity, reliability and energy efficiency benefits to our customers.

With several complex equipment that run round-the-clock under extreme conditions in a steel plant, it is essential for operators to adopt, right lubrication practices to ensure productivity and profitability.

ExxonMobil's range of hydraulic oils and greases address the requirements of the industry and strives to enable steadfast growth for the industry.

For further information, log on to mobil.com/industrial

(Communication provided by company)

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com