Radicon powerbuild solution for pug mills

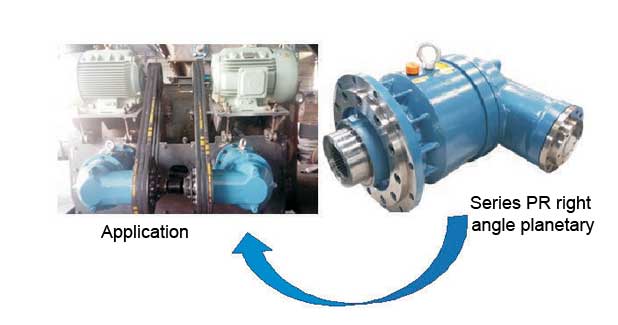

Pug mill is a kind of mixer which mixes the material based on the requirement. Different industries use different types of pug mills, e.g. foundry machines use open drum pug mill, construction industry uses drum type, etc. Types of pug mills are defined based on construction and rotating shaft.<p></p><p>This kind of application cannot be catered through standard product as it needs some special features to make it suitable for the application. Construction industry mostly uses synchronised twin-shaft mixers. Application is like two gearboxes mounted on each mixing shaft and synchronised with joint. The gearbox needs to have pulley mounting and synchronisation arrangement at input shaft.</p><p>Powerbuild team worked on the application requirement, challenges of the specific use and criticality of the dimensions. RADICON POWERBUILD has come up with a solution for pug mills used in construction industry. The company has supplied many special planetary units which are running successfully in the market. RADICON POWERBUILD has a range of up to 65,000 Nm for this application with PR series gearbox.</p><p> <span style="font-weight: bold;">Better bandwidth utilisation</span><br /> Tnew POWERLINK bus controller X67BC8780.L12 from B&R has an integrated hub for eight CAN connections. The star topology of the CAN network allows a higher maximum total cable length and better utilisation of the bandwidth. It also greatly simplifies cabling.</p><p>External CAN devices can be connected to each of the eight separate CAN lines with a standard CAN bus topology. Each line can extend out to the maximum length determined by the baud rate. All eight CAN bus controller connections are terminated using integrated terminating resistors. Full FPGA implementation allows the hub to achieve minimal throughput times. The device offers IP67 protection and is suitable for installation outside the control cabinet.</p><p><span style="font-weight: bold;">Hub optimises CAN network:</span> According to its specifications, a CAN network can only be built as a line structure with very limited branch lines. The new X67 hub groups various CAN segments into a collision domain. It functions similarly to an active star coupler in a fiber optic network. With the active coupling, the individual segments are no longer subject to the restrictions of branch lines, which greatly simplify cabling. Integrated sensor power supply: At each CAN connection, 200 mA are available for the sensor power supply. The connections are short-circuit proof. The bus controller has a wide voltage range of 9 to 32 VDC. All sensors used in the industrial and automotive sectors can be connected directly using a single cable. An additional connector allows the I/O power supply to be daisy-chained to additional modules. The M12 connection technology and use of prefabricated standard cables, commissioning teams can immediately begin setting up the machine without having to first tediously check cables. </p><p></p>

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com