Trenchless Technology Selection for New Utility Installation

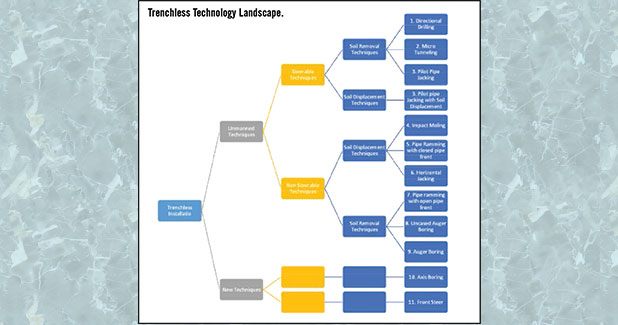

In this article, we will be discussing some key technologies and its variants in short, along with its application and limits. The frontiers of these technologies are being expanded by practitioners to solve new and emerging needs as well as in quest for better solution to existing applications. Hence the discussions in this article should be considered for broadly accepted practices and authors? personal view as boundaries are being pushed constantly. In some rare cases, we are finding ingenious contractors using more than one technology on one project for increasing efficiency and meeting project constraints.

The choice of technology among trenchless technologies mainly depend upon the broad factors listed below. The list below captures 12 such parameters; however, in 90% of the cases first four parameters determine the selection of technology and Pipe Material (5th) is chosen based on the technology of installation. We will be discussing each of these technologies in brief along with its suitability for the parameters mentioned below in the article ahead.

1.Diameter of the pipe to be installed

a. From 40 mm diameter HDPE pipe to install optical fiber to 2,000 mm diameter pipes for water and sewer networks

2.Length of the pipe to be installed

a. It?s being used for crossing small roads (20 m) to more than 3,000m for connecting utility from shore to the Island or crossing mountains

3.Soil Strata

a. Various types of clay

b. Various types of rocks

c. Cobbles

d. Back filled soil

4.Accuracy requirements if any

a. On Grade Sewerage network

b. Minimum clearance between two installed utilities

5.Material of pipe to be installed

a. Non-flexible pipes like

i. RCC pipes

ii. GRP pipes

iii. Wrought Iron pipes

b. Flexible pipes

i.Steel pipes

ii.PE pipes

iii.Optical fibre

iv.Electric power lines

6.Ground water table

7.Application

a.Optical fibre network

b.Electric power lines

c.Main gas pipelines

d.City gas lines

e.Water lines

f.Sewerage network

8.Depth requirements

9.Nature of obstacle to be crossed

10Cost & time constraints

11Availability of equipment and expert crew

12.Client preference

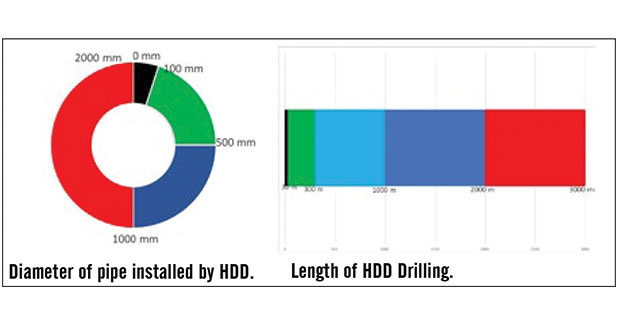

1. Horizontal Directional Drilling (HDD): Remains the most popular and widely used trenchless technology to install variety of utilities. It?s an unmanned steerable technique in which soil removal is done with the help of ?Liquid Flushing?. The technique typically involves making a pilot hole and then upsizing the same with the reamers and multiple pass of reamers to upsize is not uncommon. Finally, product pipe is pulled in.

It remains a very popular technique due to:

i.Ease of usage as typical machine is positioned above ground

ii.Easy setup and faster operations

iii.No restriction on depth

iv.No troubles with ?High Ground Water Table?

v.Its versatility

1.Diameter of pipe installed (40 mm to 2,000 mm)

2.Length of pipe installed (30 m to 3,000 m)

3.It can be used in almost all soil conditions except ?Boulders?

4.Pipe material (Flexible)

vi.Being a steerable technique, accuracy is reasonably good

vii.The equipment and expertise remains widely available

viii.Comparatively economical option in majority of application

Soil Type: All type of clay, silt, sand, weathered rock, rock, small boulders and mix soil

Water Table: Water Table remains mostly irrelevant for the HDD operations, except for the dewatering of Exit Pit for the connection of reamers and product pipe.

Pipe Type: PE, HDPE, Steel and Electric Cables

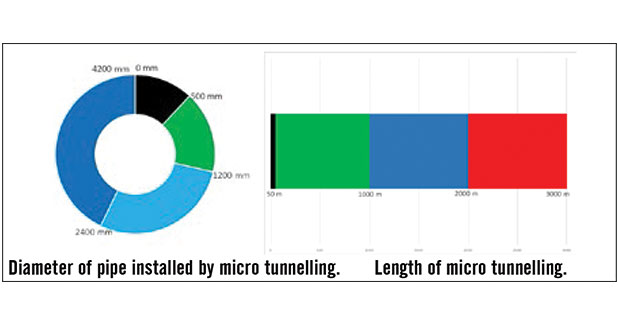

2. Micro Tunneling: The American Society of Civil Engineers (ASCE) standard construction guidelines define it as ?a remote controlled, guided pipe jacking techniques that provides continous support to the excavation face and does not require personnel entry in the tunnel?.

Some old literature restricts the diameter of microtunneling to 1,200 mm and larger diameters are defined as tunneling. In some other literature, its diameter is restricted to 2,400 mm. However, these remains mostly scementics and microtunneling principles are used for tunneling upto 4,200 mm diameter tunnels.

Further in machines with larger diameter it?s not uncommon to find ?Man Access? to replace its front cutting blade in cases where it gets wornout due to geology or in cases of mixed geology where cutting head needs to be replaced to suit the geology of that specific patch. In this method the unmanned remote controlled microtunneling machine carries out full face excavation of the working face and then ?Product Pipe? is jacked in that cavity as it goes forward.

There are many different type of microtunneling machines based on how soil is removed

Slurry Balanced: The most versatile and expensive method used for installation of piped from 500 mm to 4,200 mm diameter

Soil Balanced: Usually used for the higher diameter 1,500 mm to 4,200 mm

Auger Balanced: Usually used for smaller diameter 250-500 mm

Installation Accuracy: It?s the most accurate method of pipe installation and extensivly used for ?On Grade Sewer Installations?. Its typically guided by the ?High Precision Laser?; however, in recent times ?Gyro? is also being used in some cases.

Soil Type:

Slurry Balanced Machine: All soil type

Soil Balanced & Auger Balanced: Sand, clay, silt, quick sand

Pipe: In many cases, the pipe needs to be specially designed for withstanding the thrust of ?Pipe Jacking?.

Reinforced Cement Concrete Pipe (RCC),

Glass Fiber Reinforced Plastic (GRP) Pipe and other rigid pipes.

Ductile Iron Pipe

Vetrified Clay Jacking Pipe

Polymer Concrete Pipe

Water Table: The operation requires continous dewatering of the ?Entry Pit? Steering: With some of the modern machines limited curves in both Horizontal and Vertical Direction is possible and increases the attractivness of this technique.

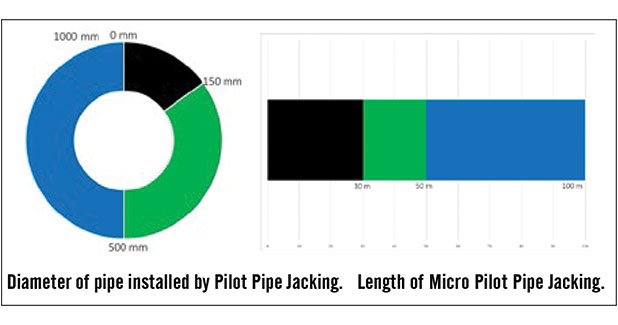

3. Pilot Pipe Jacking: A steered pilot bore is first made either with the principle of ?Soil Displacement? or ?Soil Removal? and subsequent unsteered expansion or reaming is made. The process can be completed in either two or three phase jacking a. Three Phase Jacking:

i.A steered Pilot is made

ii.Bore is expanded or Reamed

iii.Product Pipe is pushed

b. Two Phase Jacking: The 2nd and 3rd stage is done simultaneously Installation Accuracy: Intermediate accuracy as after installation of Pilot Pipe expansion is done without directional control.

Soil Type: Clay, Slit, Sand, Gravels

Pipe:

Reinforced Cement Concrete Pipe (RCC),

Glass Fiber Reinforced Plastic (GRP) Pipe and other rigid pipes.

Ductile Iron Pipe

Vetrified Clay Jacking Pipe

Polymer Concrete Pipe

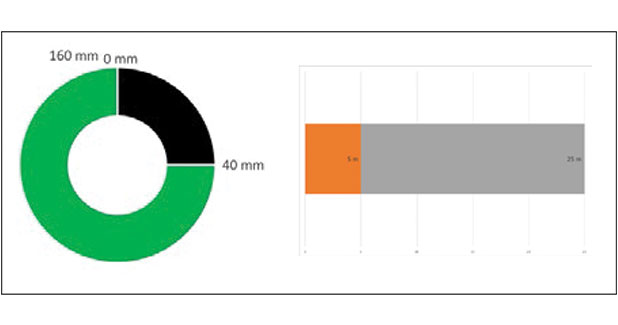

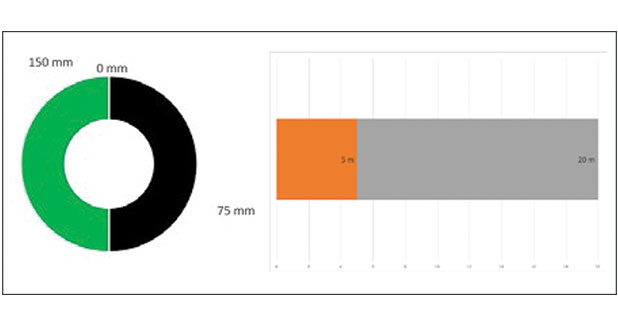

Water Table: The operation requires continous dewatering of the ?Entry Pit? Steerability: Steereability of bend radius greater than 150 m is possible 4. Impact Moling: Self actuating jacking of a compressed air operated displacement hammer with the aid of ram energy and immeidiate or latter pulling or pushing of the line into borehole created by displacement of subsoil. This remains simplest of the technique and used for very small diameter pipe installation to a short length only. Its primarily a non-steerable method.

Soil Type: Clay, Slit, Sand

Pipe: PE Pipe

Steerability: The system is susceptible to deviation its own due to soil strata differences and multistage hammer helps to keep the direction straight.

5. Pipe Ramming with closed pipe front: Jacking of a closed steel pipes string by means of ramming with simultaneous displacement of the soil. The minimum cover of 12 times of diameter of the installed pipe is recommended. Its primarily a non-steerable method.

Steerability: The system is sucseptible to steer on its own due to soil strata differences and multistage hammer helps to keep the direction straight.

6. Horizontal Jacking/Horizontal Jacking with Expander: The ground is displaced by pushing a rigid pilot tube. The final pipeline is installed by pulling or pushing behind a expander. This technique is suitable for steel pipe of diameter less than 100 mm and pipe length less than 20 m only. The method is suitable for all water permissible soil, plastic clay and looms. This primarily remains a non steerable technique and susceptible to deviation due to strata changes.

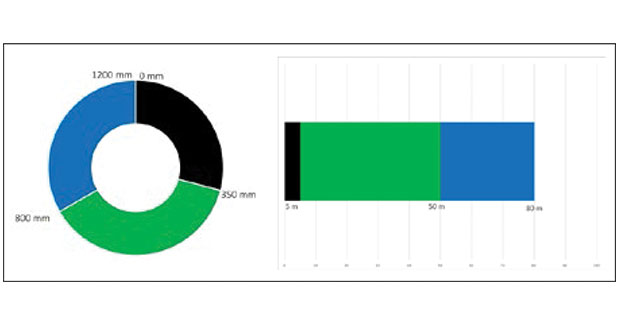

7. Pipe Ramming with Open Pipe Front: Jacking of steel pipe open at the front by means of Ramming. The earth core entering the pipe is removed continously, at suitable intervals or after completion of jacking. The installation technique requires usage of higher wall thickness pipes. A cutting show (360 deg) is installed at the front of pipe and pipe is pushed from behind.

Installation Accuracy: Its non steerable method and susceptible to deviation

Soil Type: Clay, Slit, Sand

Pipe: Steel Pipe

<350 mm 6 mm wall thickness

350 to <8009 mm wall thickness

800 to <1,200 12 mm wall thickness

>1,200 mm16 mm wall thickness

Water Table: The operation requires continous dewatering of the ?Entry Pit?

8. Uncased Auger Boring: Boring with the aid of an auger string with simultaneously removal of the loosened spoil from the uncased borehole of the starting shaft. The technique is used for the small bores of diameter from 90mm to 220 mm and length only upto 20m. This technique is only suitable for homogenious, stable soils free of groundwater. This technique is non steerable and susceptible to devation from its path due to geological conditions.

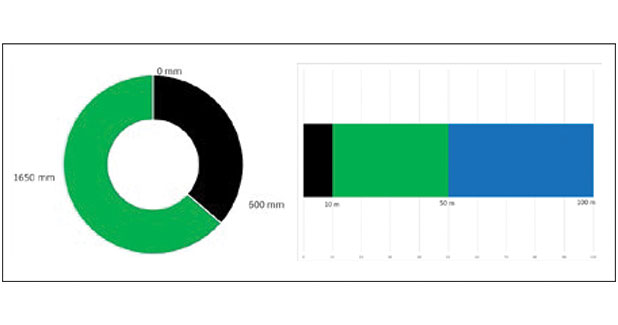

9. Auger Boring: The soil and/or rock is excavated by a rotating cutting head attachment to an auger which continuously removes the spoils. The technique is also called ?Horizontal Thrust Boring?.

Installation Accuracy: It?s basically a non steerable method and susceptible to deviation from the path. The manufacturer recommendation quotes deviation upto 2% of the Jacking length. Howeverl some of the modern machines are equipped with some steerability and at times HDD cable transmitters are used to measure and correct deviations.

Soil Type:

Most soil types can be drilled in this method by using appropriate cutters Pipe: Steel Pipes are usually used with Auger Boring application

Water Table: The operation requires continous dewatering of the ?Entry Pit? 10.

Axis Boring: In this technique from a launch pit, laser guided camera equipped drill head is launched, the rotating drill head cuts the soil and spoils are vacuumed out through the hollow section in drill head and subsequently drill casing to vaccum tank. The pipe sections are added behind to keep increasing the length. The product pipe is either installed using pipe jacking method or pulled back by the after removing the drill head. The system has been designed by the leading trenchless equipment provider Vermeer manufacturing.

Installation Accuracy: It?s one the accurate method of pipe installation and it has been specially designed for installing ?On Grade Sewer? and guided by guided by the ?High Precision Laser?.

Soil Type:

Rock, Shale, Reef, Clay, Sand, Mud, Silt

Pipe:

Ductile Iron Pipe

Vetrified Clay Jacking Pipe

PVC

HDPE

Steel

Water Table: The operation requires continous dewatering of the ?Entry Pit? 11. Front Steer: Its basically a Auger system with a Laser Guidence system to increase the accuracy of the ?Auger Boring system?. The manufacturer Bohrtec claims that with ?Optical Guidence System?the accuracy of the system is +/- 25 mm in all directions.

The trenchless techniques discussed above are by no mean exaustive and there are so many other variants of these technique are available in the market. Further we once again reiterate that the range of operations mentioned in the article are indicative and some practitioners always find a way to execute jobs beyound the usual capability of the techniques.

The author is Managing Director of Digital Control Incorporation, Indian Subcontinent & Middle East Operations.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com