What’s Ahead in CE Manufacturing Sector

The construction equipment industry is paralleled to the growth of the nation with its prime contribution layed towards infrastructure development. With major development projects getting nod which is linked to smart cities, metro lines, road, and railway establishments, new airports at tier 2 cities, and others are seen as growth drivers for both rural and urban development. The new projects open up significant opportunities for the construction equipment industry to develop thrust on building infrastructure. It is a momentum shift for manufacturers to deliver to growing needs with best-in-class technologically advanced systems. With more diversified applications and operating conditions expected, manufacturers need design flexibility and adaptability of construction equipment as per specific demands.

Construction equipment OEMs are aimed at intensifying products with the latest technologies adding higher productivity, lower maintenance, easy operations, and remote connectivity. However, OEMs are poised with challenges when it comes to the production and monitoring process. The shop floor is built with machines operating on multivendor controllers which indirectly shoulders operator expertise in functioning those machines and maintaining them. Integrating additional systems for data analysis and process monitoring adds to the burden on operational costs. With digital technologies entering the shop floor, scaling existing controls to new ecosystem mounts to be a humongous task. These challenges in everyday operation have increased pressure on OEMs to explore advanced automation systems that can control the production process, monitor, and diagnose machines and support digital adoption for future needs.

Unified automation for the complete shopfloor

The advanced factory automation solution from B&R – Edge Controller addresses the growing demands of the construction equipment industry with ease. Edge Controller is a powerful bundle of control and SCADA into a single system. It opens up multiple possibilities for manufacturers to take control of production lines integrating with existing systems and bringing them on a common platform. In addition, Edge Controller is also known for its integration with the multi-generation, multi-vendor machines on the process line. Whether the line assembles, excavators, backhoe loaders, bulldozers, or lifting cranes, Edge Controller is programmable for all different types of products. OEMs can easily expand the process line with additional machines and accessories and link multiple thousand remote IOs with Edge Controller. The powerful controller with easy shop floor integration adds value to the manufacturer in terms of future expansion.

Data management made seamlessly

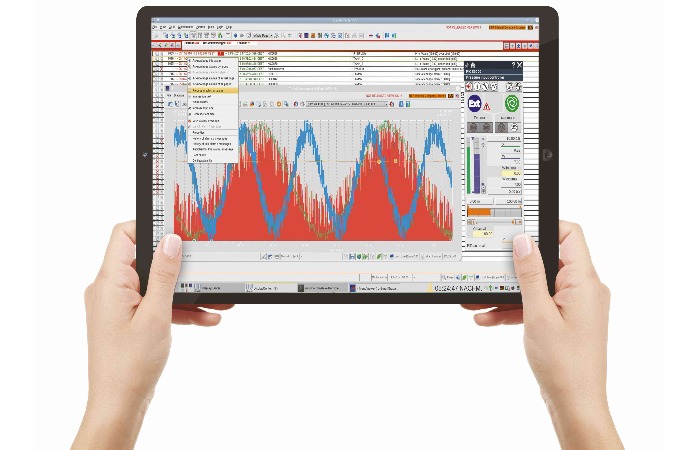

Edge Controller is more than just a control system. Construction equipment manufacturers can take advantage of SCADA with Edge Controller. It is built with modular software components that support data archiving and analysis. The production line has KPIs to achieve to ensure higher productivity, increase machine availability, and adhere to quality gates. Data plays a vital role to enable production teams to achieve these goals. Integrated PDA (Process Data Acquisition) from Edge Controller consists of ready-to-use modules that collect data from the machine in runtime and present it through dashboards and reports. The data from machines are collected using supported fieldbus connectivity and presented in reports customised to the specific needs. Customisation is an integral part of Edge Controller. Based on manufacturer-specific templates, reports are designed and linked with the database. Manufacturers access real-time and historical databases using a single system. It eliminates the costs of additional servers to maintain historical data of the process line.

Edge Controller is instrumental

in data management. It has extensive support for recipe management, user management, and alarm management. Manufacturers leverage central user management with the latest username and password policy norms used for maximum data security. Audit reports generated from the Edge Controller keep track of users modifying, adding, or deleting key parameters and notify the process monitoring team. The alarm notifications are shared with respective maintenance and production teams using email and SMS, enabling them to take quick actions to address the alarms. The PC-based performance of the Edge Controller supports production teams to scale the system to handle multiple product outputs. With easier recipe management, operators navigate through touch-friendly screens and make machines adapt to new product line-ups.

Data security at all levels

Edge Controller brings in the transparency of shop floor data by integrating multi-vendor machines on the production line. It supports open communication protocols such as OPC UA and MQTT that enable the production line to connect and share data mutually with IT systems in a unified and more accessible way, thereby offering complete visibility of end-to-end operations on the shop floor. With the increased volume of data, there is also raised concern on data security by the manufacturers. They are keen on ensuring data generated from the process line is accessed only by authorized personnel. Hence it adds to the responsibility of the automation system to address data security demands. Edge Controller uses best-in-class security features to ensure data is secure throughout the operation. It runs on Linux based operating system which gives utmost priority to data security. In addition, Edge Controller obliges end-to-end encryption and data certificates to give a unique advantage to an authorised user for data access.

Increased attention to machine health

The shop floor of construction equipment manufacturing mainly consists of machine tool lines, assembly lines, paint shops, and final inspection lines. Each line is synchronised to ensure free flow of production with maximum uptime and effective utilisation of resources. The maintenance team comes under pressure to ensure seamless production by eliminating unscheduled downtime. Edge Controller with its integrated component for predictive maintenance – ConMon (Condition Monitoring) allows the maintenance team to gather first-hand information regarding any anomalies in the production process. ConMon is an intelligent condition monitoring function, which interacts with vibration sensors connected at key points of the machine where possible damage may occur due to abnormal vibrations. The data is recorded in real-time and presented as trends and described through reports for maintenance personnel to take corrective actions and prevent a line from unscheduled stoppage. With the EnMon (Energy Monitoring) component of Edge Controller, manufacturers leverage the benefit of monitoring energy used through various mediums and track their consumption levels in real-time. Energy data play a vital role in the sustainability goals of organisation

and Edge Controller is a prominent enabler to achieving them.

Tailor-made solution for smart factories

A continuous innovation cycle is significant for comprehensive development in the construction equipment industry. Manufacturers are driven by key facets of the process to ensure optimum performance, improve machine health, upscale for digital adoptions, and reduce operational costs. Therefore, adopting a scalable factory automation system is critical in creating a differentiation factor. Edge Controller from B&R offers tailor-made solutions for complete factory automation including accurate monitoring of production, maintenance, and energy data. With powerful software and scalable hardware, Edge Controller proves to be a single system that brings flexibility to the production line and makes them future-ready.

The article is authored by Himanshu Sharma, Head – Marketing & Corporate Communication, B&R Industrial Automation.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com