?Zero-Incident? Construction Sites

The Indian Construction Equipment (CE) industry is going through a growth phase. It is evolving faster compared to a decade ago. With the new government approach being high on governance, their initiatives have opened doors to new and multiple infrastructure projects. The annual budget also emphasised on infrastructure growth, leading to a spurt in the number of projects that have been initiated.

Given the background of growth in the CE industry, there is a huge gap to match the demand for number of workers required. Millions of construction workers in India are employed and the number is rising. This number has led to the laxity towards safety and health related issues.

Amidst this growth, safety issues/policies and practices often get overshadowed at construction sites. There is a lack of an apex body or organisation to deal with these issues, coupled with a lack of legislation and standardisation. The exact number of deaths caused due to construction activities is unknown but the reasons resulting in death range from occupational hazards like diseases, mental and physical stress, disability and injuries to major disasters at the site.

Safety is of prime importance for any project to succeed and should be a part of an organisation?s DNA. Safety at high-risk locations like a construction site gets even more critical and the safety measurements can be key indicators to predict the success of a project.

A zero occurrence safety initiative should be the motto today. Construction sites are prone to maximum incidences and India leads in the number of construction site accidents as reported in a paper published in 2012 by academician Sarbeswara Sahoo at the Mahatma Gandhi Labour Institute in Ahmedabad. These accidents are usually a result of one or combination of these: improper illumination, improper material handling and storage, improper walking and working surfaces, obstructive and unclean floors and aisles, improperly stored trenches and excavations, badly maintained tools, improper scaffoldings, baldy maintained construction equipment, etc.

While safety is a personal responsibility, it is also an employer?s liability. A substandard approach towards safety is usually a sign of a low-quality project site. Safety is a key to not just reduce project costs coming out of accident management (compensations), but is also the indication of an emotionally strong employer who values people assets and strives towards a no-harm, healthy workplace.

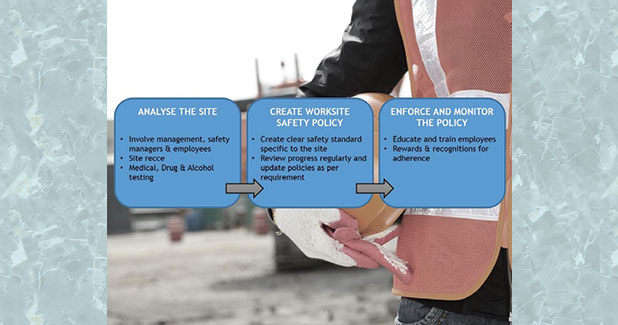

Organisations should focus on a zero-incident, safe construction site and must pen down safety norms including:

Involvement of the company officials, safety managers & employees: The construction site owner should be actively involved in promoting safety norms at his site. He should employ professional safety managers or site supervisors who will look after day-to-day safety norms and check for any slack that can lead to accidents. The safety managers should have thorough knowledge and control of the site. The employees should be trained to follow safety procedures. Special training should be given to employees who handle heavy equipment like cranes, excavators, lifting machines and any tool or equipment that involves electricity. The employees should be made to understand the importance of applying safety guidelines and how minor glitches can lead to major accidents. It might be helpful to print out safety norms in the local language for workers who cannot read English.

Analysis of the site?s risk along with hazard prevention and control: Before beginning work at any site, safety managers should do a detailed recce of the location and find out what are the risky areas and where there is even a slight possibility of accidents. These should be taken care of, even before a construction site starts operating and these inspections should take place every fortnight depending on the progress of work and changes occurred hence. The safety manager should ensure that false work, scaffolds and fences are designed and erected by professionals, according to the design requirements. No one should be allowed to alter any construction without authorisation. The material used to erect these structures should be sturdy and of good quality metals. The false work and scaffold should have a steady working platform or base. Fencing is another important aspect when it comes to working in dangerous or risky places. Checking fencing regularly and ensuring that they are repaired in case of any damages should be a priority. Equipment should be checked for wear and tear before operations.

Safety managers should also check possibility of fire in the site. No welding work should be done close to any inflammable or explosive items. Fire extinguishers should be kept handy at the site and the workers should be aware as to how to use them. An escape route should be devised in case of a fire.

The safety manager should be prepared to deal with any minor or major accidents in case they do take place. Basic first aid with medicines to deal with cuts, bruises and burns should always be kept handy at the site. The safety manager should have all necessary emergency contacts of ambulance, doctors and closest hospitals.

Medical, drug & alcohol testing: Every worker should go through alcohol and drug tests so that lives are not lost due to their negligence. Consumption of any form of drug or alcohol should be strictly prohibited at sites. A strict vigil should be kept at all times on workers so that they do not indulge in such habits.

Every worker should go through a medical test before they start working at sites to check whether they have any medical conditions that might arise during the time they are working.

Education & training towards safety policies and zero-incident initiatives: Construction site owners should initiate trainings for safety managers and site supervisors who in turn can train the employees on safety norms, guidelines and explain as to how not following them can lead to loss of life. Employees should be encouraged to bring any safety concern to the notice of the safety manager so that they can be dealt with immediately.

Clear communication, incident reporting & corrective action plan: It should be made sure that the communication between the safety manager and the workers are always clear. A safety manager should make sure that what he says is understood and if there is a language barrier, it should be dealt with. The communication between the equipment handler and site workers should also be clear as absence of this can lead to major mishaps at the site.

The reports and concerns raised by employees should be dealt with immediately and there should be no negligence on the employer?s part. In case any accident is reported, it should be documented and corrective action should be taken so that the same mistake is not repeated. The reasons for accidents should be carefully investigated and included in future trainings and safety guides.

Rewards & recognitions for adherence to safety: Employees should be given regular perks and recognitions for maintaining safety in the site. Construction sites which have not had even a single minor accident should be given rewards so that employees are encouraged to notice minute glitches and report them immediately. This will encourage employees not only to take care of their own safety, but also the safety of colleagues around them.

Safety has been a non-issue so far. It is time that construction site owners and labour bodies take up this issue on priority. There should be a 360-degree approach to deal with safety where all parties involved in a construction project should be a part of designing a safety strategy.

Besides ensuring safety at the site, workers should be provided with residential facilities with adequate sanitation. Feedback systems should be made more effective which can be used to design a safety strategy involving safety professionals, labour unions, construction site owners and any other non-governmental organisation that might be involved. More researchers should be encouraged to take this issue up and garner reports and possible solutions for deaths and injuries caused. Safety audits should be conducted at sites to monitor the working conditions. The government should play a more active role towards ensuring high standards of safety in the entire construction industry. As a personal onus, one must adhere to the safety norms chalked down by organisations, as a zero-incident construction site is a two-way road to success and will fail if one fails.

Reduce Health Hazards

- Ensure ventilation at the worksite

- Decrease use of hazardous substances to the minimum

- Provide respiratory equipment for protection against dust, vapour and gases

- Provide protective eye gear for workers working at the welding site or exposed to chemical splashes and headgear for workers dealing with heavy equipment

- Provide training on personal hygiene

- Ensure good housekeeping.

Ensure a safe worksite

- Set emergency alarms

- Train employees and provide printed safety guidelines specially for those who handle equipment

- Provide appropriate safety gears such as helmets, shoes, safety belts, gloves, etc.

- Provide safety nets in places where there is a risk of falling

- Check construction site before project begins for risks of accidents and mitigate any potential threat

- Keep first aid handy

- Prohibit consumption of any form of drugs or alcohol

Key Recommendations

- Regular safety audits

- Safety training for unskilled workers

- Ensure employees have access to and know the importance of personal safety equipment

- Government involvement in reviewing and upgrading safety standards and legislations

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com