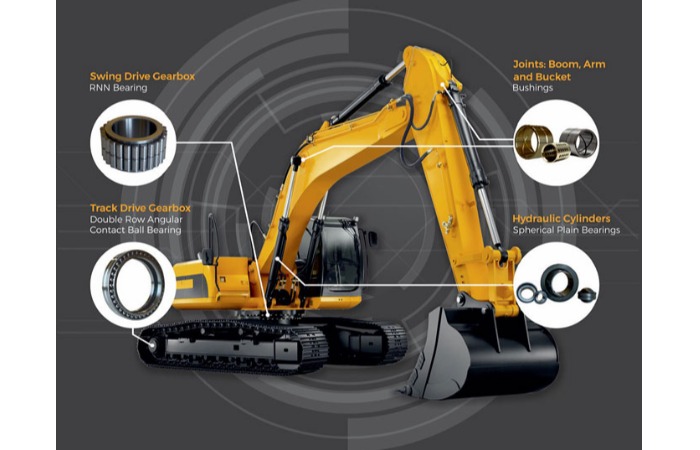

CCTY Customised Solutions for Construction Equipment

As construction equipment evolves to fit end-user requirements, the bearings used must become stronger and more reliable as they operate in some of the most demanding environments. While bearings may be thought of as standard, off-the-shelf components, design engineers know that customisation plays a critical role in ensuring predictable performance and long life with reduced maintenance. To accommodate space constraints and application-specific performance requirements, modifications can be applied to internal geometry, materials, coatings, sealing, lubrication, and internal clearances.

Loads are anything but standard

Unlike industrial machinery that operates under steady loads, construction equipment experiences highly variable forces. Bearings in boom pivots, articulation joints, and swing mechanisms are subjected to fluctuating radial and axial loads, impact forces, and frequent starts and stops.

Customising bearing geometry, clearances, and hardness allows engineers to better match the bearing to the true load profile, reducing localised stress and premature wear.

Adjusting to environmental conditions

Construction sites are surrounded in abrasive working conditions that include dust, mud, water, vibration, and extreme temperatures. To address these challenges, bearings can be designed with:

- Metal shields or seals with multi-lip profiles to better exclude debris and retain lubrication. The material can also be chosen for resistance to abrasion and ozone requirements.

- Corrosion-resistant surface treatments. Bearings working in wet or rust-prone environments can benefit from an added layer of protection with zinc plating, phosphate coatings, chrome plating or e-coating. Surface treatments provide an extra barrier to external elements while promoting a longer operating life.

Material and lubrication selection

Working with a bearing manufacturer that understands construction equipment is critical, as industry expertise helps to identify the right materials and features to extend component life. Depending on the application, bearings may use high-strength alloy steels, specialized heat treatments, or wear-resistant coatings.

For machines with hard-to-reach bearings or bushings, self-lubricating liners are incorporated to eliminate the need for regular re-greasing. The type of lubrication – grease, oil or PTFE – can also be selected based on performance goals.

Misalignment and structural flex

Large construction machines are not perfectly rigid. Frame flex, uneven terrain, and assembly tolerances can introduce misalignment at bearing locations. Customized rod ends and ball joints can be designed to accommodate greater angular misalignment or axial movement without sacrificing load capacity.

This flexibility also protects adjacent components and improves overall system reliability. For example, spherical plain bearings in an excavator can provide very high load capacity while managing large misalignment angles.

Integration with surrounding components

Customisation to the bearing’s outer diameters and mounting features are often used to integrate seamlessly with the housing. When the bearing and housing are shipped as a single unit, it simplifies assembly, improves load distribution, and can reduce the number of components required, such as tie rods that are preassembled with ball joints or spherical plain bearings.

By aligning bearing design with operating conditions, equipment manufacturers can achieve longer life cycles and more consistent performance. In an industry where longevity and uptime are critical, customised bearings are not a luxury, they are a necessity.

Communication from the management of the company

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com