Customising CE Motion Control

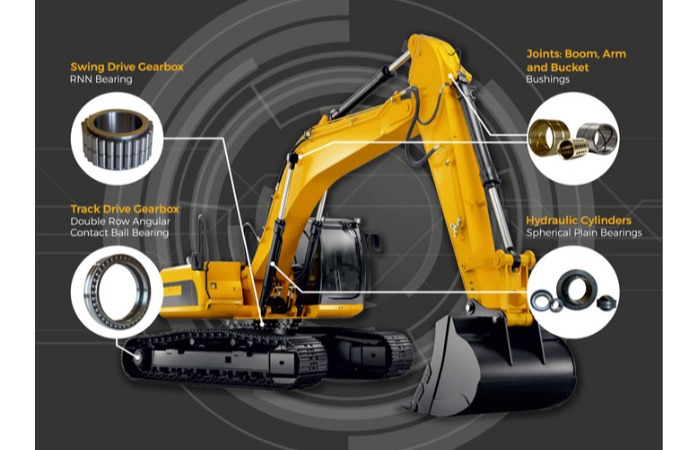

The construction equipment industry relies on components that can withstand extreme loads, constant shock, abrasive conditions, and continuous movement. Whether in excavators, wheel loaders, cranes, or bulldozers, the parts inside must deliver strength and reliability day after day. Motion control components such as bearings, bushings, rod ends, ball joints, and linkage assemblies play a critical role in ensuring that these heavy-duty machines operate smoothly and safely. To extend component longevity, OEM designers can leverage various design and material options.

Spherical plain bearings are commonly used in pivoting and oscillating joints found throughout construction machinery. These bearings are designed to accommodate high radial and axial loads while maintaining consistent movement under harsh conditions.

To extend service life in environments with high contamination or limited lubrication access, these bearings can be designed with hardened steel, corrosion-resistant materials and maintenance-free liners.

Bushings: Built for endurance

Bushings are vital wear elements in oscillatory applications where relubrication is not feasible or not preferred. They provide a durable interface between moving parts, helping to reduce friction in areas like lift arms and cylinder mounts.

Depending on the application, bushings may be produced in metal-backed, solid bronze, or composite designs, with options such as lubrication grooves for grease or oil, or self-lubricating PTFE liners to enhance performance.

Custom bushings can be manufactured to application specific tolerances. Custom bushings can achieve longer life when the design, materials, and running clearance are correctly matched to the load, speed, and environment. These benefits are particularly useful in construction equipment where reduced maintenance requirements can be an advantage.

Rod ends and ball joints provide flexibility and strength within steering systems, hydraulic cylinders and control linkages. Because these applications often involve both dynamic motion and static load, the components must be manufactured with tight tolerances and appropriate material pairings.

Rod ends can be fully customised to meet the specific mounting geometry and motion requirements of the application. In addition to greaseable or maintenance-free versions to match the equipment’s service needs, other customisations may include optimised clearance, tailored friction torque and application-specific swivel angles. They can be manufactured with hardened steel alloy housing, two- or three-piece designs as well as liners with PTFE or bronze.

Ball joints can be engineered with appropriate housing strength, ball stud hardness, liner materials, and retention features. Push-out/pull-out loads ensure the joint stays assembled, while the overall design, material hardness, stud geometry, surface finish, and liner selection determines its overall performance.

Complete linkage assemblies

Many OEMs choose to source fully assembled linkage systems like steering tie rods, control arms, and V-links rather than individual components. Preassembled linkages are assembled to controlled clearances and torque specifications to ensure consistency and reduce OEM assembly variation. This can help reduce sourcing complexity, and ensure that each piece is optimised to work together as part of a unified system.

Construction equipment often has unique performance requirements, and motion control components must be tailored accordingly. Engineering collaboration between OEMs and component suppliers helps ensure that key factors such as load capacity, wear, sealing, fit, and friction levels are aligned with the demands of the application.

From bushings designed to handle heavy shock loads to bearings engineered for smooth articulation in harsh environments, motion control components are essential to the efficiency and longevity of construction machinery. When designed and selected with the application in mind – and with the right manufacturer – these components help equipment run stronger, run longer, and maintain performance in the toughest conditions.

CCTY’s product line includes rod ends, spherical plain bearings, tie rod assemblies, deep-groove ball bearings, RNN bearings, ball joints, inner and outer rings, and custom solutions. Contact a CCTY engineering specialist at +91 9823017144 / +91 9601495610 or by emailing info.in@cctygroup.com to discuss your motion control needs.

Communication from the management of the company

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com