Search

Engineering the Unseen

Hidden within every crane and excavator, bearings quietly shoulder extreme loads, enabling reliability, uptime and efficiency across India’s fast-growing construction landscape

Timken India to start making CRBs, SRBs locally at Bharuch

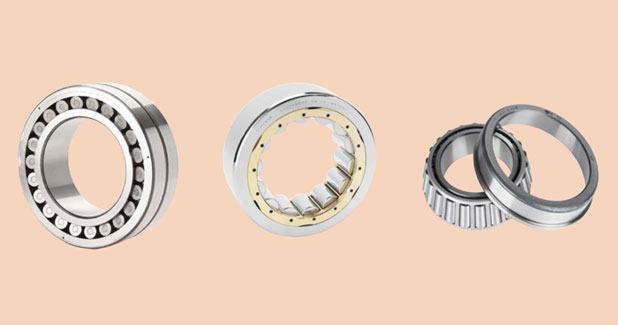

Timken India plans to set up a new facility at Bharuch in Gujarat to manufacture spherical roller bearings (SRBs) cylindrical roller bearings (CRBs) and other components.

Timken India to start making CRBs, SRBs locally at Bharuch

Timken India plans to set up a new facility at Bharuch in Gujarat to manufacture spherical roller bearings (SRBs) cylindrical roller bearings (CRBs) and other components.

Maximizing Articulating Joint Life in Compactors

A compactor’s ability to reduce air pockets and increase load-bearing capacity make it vital for construction and roadwork.

Improving Machine Productivity

While the pandemic affected all industries, it positively contributed to the bearings industry. By accelerating value chain processes, and building future capabilities, the industry quickly adapted to meet the demands.

Unlocking opportunities

Though the ongoing COVID-19 pandemic has put a brake on the growth of the bearings industry, the market is expected to bounce back and continue to grow from next year onwards.

BEARING IT ALL!

Unlike passenger vehicles, when it comes to construction equipment applications bearings should be compatible with loads and harsh working conditions. Construction and mining are mostly encountered with dust, mud, and huge loads. Bearings for construction and mining applications must be rugged enough to bear these extreme conditions. For such conditions, the various ranges of bearings like cylindrical roller bearings, spherical roller bearings, tapered roller bearings, plain bearings and slew ring bearings are used as per the application within the equipment. Such bearings will provide longer life and higher efficiency to the equipment and machinery. With customers now looking for more than just a bearing supplier, most of the bearing manufacturers are looking forward to improving the product features to live up to the expectation from customers. In any industry segment, be it is automobile, power, or industrial machinery, the concept of lightweighting is fast gaining momentum as it leads to fuel saving, resulting in overall economy. Customers would need more reliable systems as they are not only looking at bearings, but also sub-assembly systems such as housings, lubricants, and additional components like seals. Different equipment will require different application requirements. Considering this, bearings manufacturers are also focusing on customising their products. The Special Focus section elaborates more on the bearings for CE applications. Automation plays a major role in the productivity and efficiency of a system or process. Painting is a major part of construction equipment manufacturing process. One of the significant areas to maximise availability in construction equipment manufacturing plant is the paint shop. Paint provides aesthetic value and boosts physical properties of equipment. It offers durability, resistance against corrosion, adds mechanical protection, and guards against weather conditions, since equipment are typically deployed in all terrains and conditions. Edge Controller from B&R helps to monitor paint shops, increase efficiency and provides transparency. The Technology elaborates on the automation solution in paint shop. Another Technology highlighted is that Siemens and IBM announced the availability of a new solution designed to optimise the Service Lifecycle Management of assets. The new solution establishes an end-to-end digital thread between equipment manufacturers and the owner/operators of that equipment.

Maximising bearing life in construction vehicles

New equipment and in-cab features are evolving to fit consumer preferences. The bearings used for these applications must also follow suit with higher performance capabilities and enhanced reliability.

The bearing industry outlook is good for next two years

NTN has been a leader in bearings for the construction equipment (CE) segment. Ramnath Shenoy, Executive Director, NTN Bearings India, elaborates more on the products and solutions from the company.

Poised to Grow

Bearings play an important role in the smooth operation of construction equipment. Construction and mining equipment work in harsh and challenging conditions performing heavy-duty jobs, compared with the passenger vehicles.

Flow of innovations

Hydraulic hoses have come a long way to become an innovative product that has all the features needed for efficient flow of the fluids with adequate strength to withstand high pressure, resistance to corrosion, flexibility for ease of use and more.

Rolling innovations

Bearings for construction and mining applications have seen innovative developments in the recent times. With the construction and mining equipment market is growing, the momentum of innovation in bearings is to pick up in the coming days.

ROLLING AHEAD

Bearings make an important component of a machine that enable a smooth movement of the machine parts. Most bearings facilitate the desired motion by minimising friction.

Construction equipment is our growth engine

The Indian market offers enormous growth opportunities in the construction equipment industry.

We offer maintenance-free product options to OEMs

In response to the 'Make in India' campaign, Indian market is becoming the manufacturing hub for major global original equipment manufacturers (OEMs). As a Tier-I supplier to the construction and agricultural market, it was only logical for CCTY Bearing to secure an in-country presence to be closer to customers to respond to their growing demand for our products.

Rolling On Smoothly

Bearings are an integral part of equipment which increase efficiency by reducing friction, while maintaining the operational requirements. In this fast moving age of industrialisation, efficiency is the key to success. Construction equipment operates in very demanding environments

Application-Specific Sensorised Bearing

Best-of-class and best-of-breed bearings are the resultant product of a combine comprising equipment OEMs, bearing manufacturers, material developers and lubricators.

?Bearings? for Long Life

India is set to be one of the biggest manufacturing hubs in the world, within the next few years. What does this entail for the bearing industry? Will ?Make in India? campaign boost the industry? According to Hrishikesh Kulkarni, Business Head - Drives and Off-highway, Industrial Market, SKF India the government?s call for ?Make In India? has sent out positive cues to the global manufacturing community.

Orbit Bearings onto a New Growth Phase

Orbit will be opening its new factory early next year as a part of its ambitious growth strategy. The bearings segment in India has come a long way in the last decade showing rapid growth

Bearings: Brother in Arms With Manufacturing

Make in India initiatives project India to become one of the largest global manufacturing hubs, and is a clarion calls to the international manufacturing community which augers well with the domestic aspirants.

Bearings for Smooth and Durable Functioning

Not as interesting or inspiring as a tiny transistor in an electronic circuit, a bearing is as important as a transistor when it comes to the smooth functioning of a machine.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com