Search

Budget FY27: What It Means for India’s CE Sector

The Union Budget 2026–27 has delivered a clear and positive signal for India’s construction equipment (CE) industry

Budget FY27: What It Means for India’s CE Sector

With record public capex and a long-awaited incentive scheme for equipment manufacturing, the Union Budget signals a turning point for India’s CE industry amid slowing demand.

Union Budget 2026–27 Marks a Milestone for Construction Equipment Manufacturing

ICEMA’s Long-Standing Demand for Incentive Scheme Announced

Rs.75,000 cr Push

How policy, private capital and heavy equipment are redefining India’s port equipment industry.

Bauma CONEXPO INDIA 2023 - Highlights

The trade fair for construction equipment industry garners excitement!

Make in India initiative has been pivotal to our re-entry into the market

Lintec & Linnhoff launched its new Linnhoff DRX DurableMix asphalt plant series. It also launched its locally manufactured Linnhoff TSD1500 MobileMix asphalt plant. The plants will be built by its newly appointed licensed manufacturing partner, Gainwell Engineering.

Volvo Trucks is shifting gears and focussing on driving customer success

Over the last 20 years, through our high-technology innovative products and services solutions, Volvo Trucks has been driving progress in the Indian market.

A Massive Success

More than 10,000 high-tech products were exhibited during the four-day event spread over 150,000 sq m.

Efficiency will continue to play a major role in the future

Volvo Penta offers a complete range of engines from 105 kW to 565 kW. Miron Thoms, Vice President and Head, Volvo Penta India shares more on the upcoming market trends in diesel engines.

Efficient power for Indian mines

Volvo Penta offers vast range of engines for construction, mining, material handling and agriculture equipment globally. Miron Thoms, Vice President & Head, Volvo Penta India, elaborates on the company's India market plans.

Safe lifting solutions

A global leader in the manufacture of high-technology PET container production machinery, ASB International Pvt Ltd, is equipping its major export-oriented plant near Mumbai with some of Konecranes' most advanced lifting technologies to enhance its quality, safety and cost-efficiency.

Piggybacking earthmovers growth

Transportation of raw and processed materials to the desired location is the next but most essential activity arising out of earthmoving. In the infrastructure space, 5-35 tonne payload capacity tippers and dumpers are extensively utilised for this purpose.

Providing Constructive Solutions

Currently representing 20 reputed construction equipment manufacturers around the world, SEPL plans to continue introducing new high-technology products in India. Salgaocar Engineers Pvt Ltd (SEPL) is one of the renowned distributors for marketing earthmoving, mining and construction equipment

Engines of Future

Latest environmental norms, best fuel efficiency and low OPEX costs, dictate developments of new generation engines. Latest environmental norms, best fuel efficiency and low OPEX costs, dictate developments of new generation engines.

TIL Launches Pixef and Crusher Plant

Til launches Pixef, a first of its kind, versatile 15T hydraulic mobile and multitasking crane for slew, pick-n-carry and carry deck applications.The focus is on safety. The 15T category of pick- n- carry cranes available in the market hitherto are designed and built on tractor chassis causing serious risk of stability during load handling as well as exposing the operators into risk due to lack of safety devices and controls.

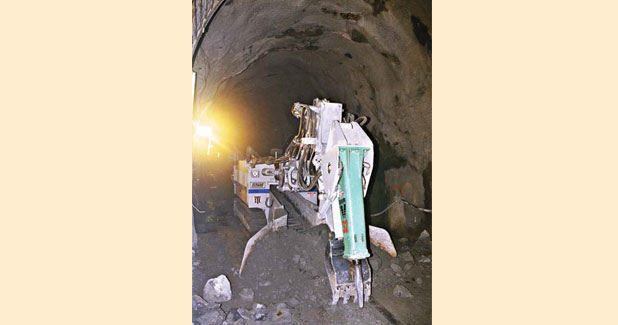

Our equipment are focused on better process management, time and cost saving.

By virtue of our acquisition of GIA AB and MEYCO in 2011 and 2013 subsequently, Atlas Copco is the preferred partner for major construction companies to complement their tunne?lling operations with shotcrete machines, locomotives, ventilation systems, conti?nuous loading machines, pipe-roofing and radial bolting system, grouting equipment.

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com